International shipping does not follow a fixed rhythm throughout the year. At certain times, parcels begin to move more slowly, status updates appear less frequently, and delivery windows gradually widen. These changes usually reflect broader pressure within global logistics networks rather than isolated shipping issues.

This situation is commonly associated with peak season shipping—a phase when demand for cross-border delivery surges within a limited timeframe. As order volumes rise, workload increases simultaneously across warehouses, transport providers, customs authorities, and last-mile delivery services.

Recognizing how peak season shipping reshapes normal logistics flow helps buyers place delays in context and reduces unnecessary concern when international shipments take longer than expected.

What Does Peak Season Shipping Mean?

Peak season shipping refers to extended periods in which international parcel volumes grow faster than logistics systems can process them at standard speed. Instead of brief interruptions, these high-demand phases often persist for several weeks and frequently affect multiple regions at once.

Peak season shipping is most commonly observed during:

- Major promotional campaigns on Chinese e-commerce platforms, including 618, Double 11, and Double 12

- High-volume retail periods such as Black Friday and the year-end holiday season

- The surge in outbound shipping before Chinese New Year

- Recurring seasonal buying cycles linked to regional or academic schedules

During peak season shipping, parcels continue moving through the network, but waiting lines develop at different stages as processing capacity becomes constrained.

Why Peak Season Shipping Leads to Delays

International shipping operates through a sequence of dependent steps. When volume rises across all stages at the same time, overall speed becomes limited by the most congested point in the process rather than average system capacity.

How Peak Season Shipping Impacts Each Stage of Delivery

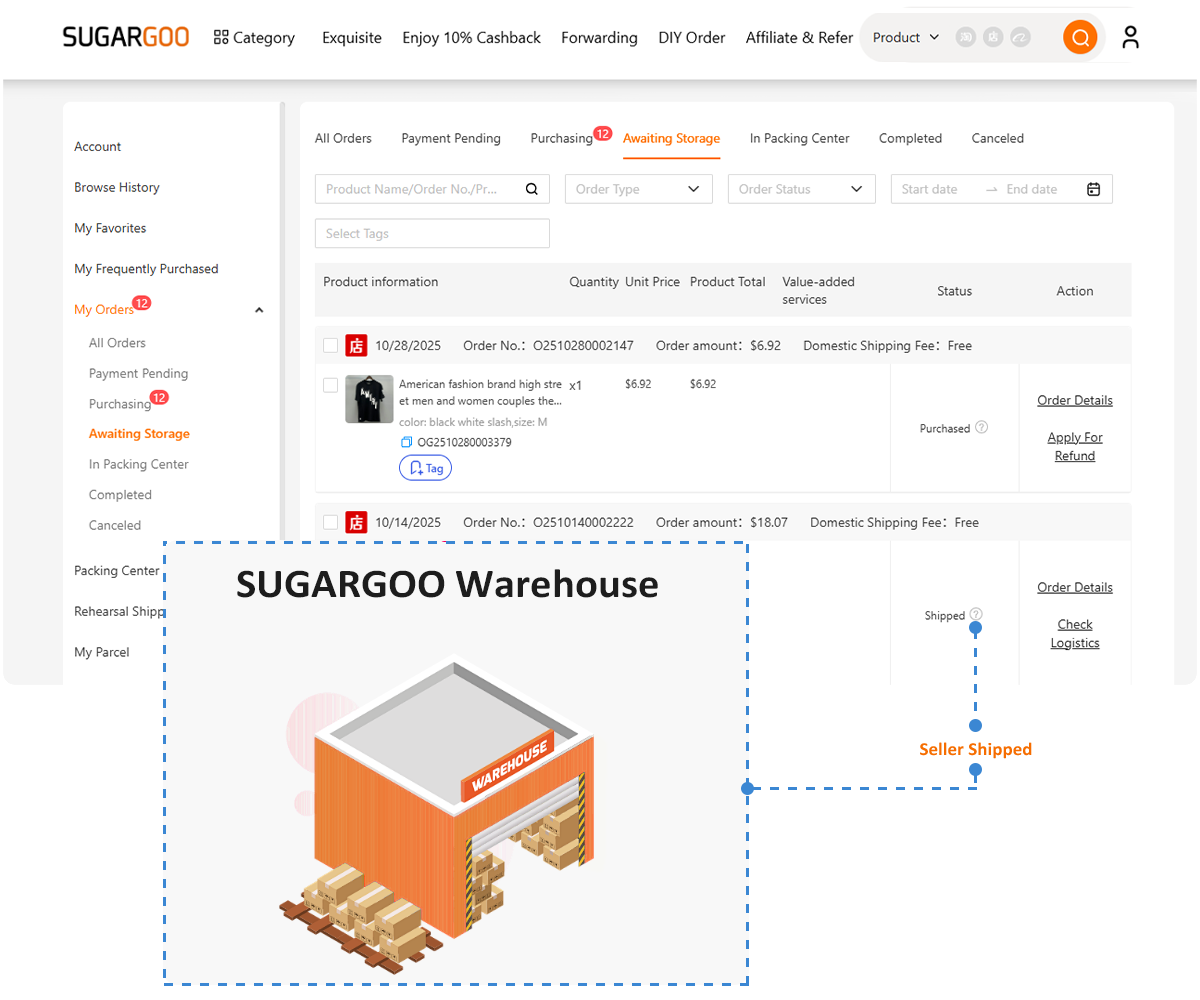

Warehouse Intake and Order Processing

The first slowdown often happens before a parcel enters international transit.

During peak season shipping:

- Sellers may dispatch orders later than usual

- Warehouses process incoming parcels in batches

- Quality inspections and consolidation require additional time

- Lower-priority shipments may wait longer before outbound processing

At this stage, tracking may show little or no movement even though the parcel has arrived at a facility.

Domestic Transport and Export Handling

Once processing is complete, parcels move into domestic logistics networks.

Peak season shipping commonly leads to:

- Limited availability of trucks and linehaul transport

- Congestion at export hubs and sorting centers

- Reduced access to outbound flight capacity

- Slower export clearance procedures

Movement continues, but departure schedules become less predictable.

International Transit

International transit is particularly sensitive to peak season shipping pressure.

Common effects include:

- Fewer available cargo slots on preferred routes

- Longer transfer times at international hubs

- Increased reliance on indirect routing

- Delays even on premium shipping services

Transit time becomes more variable as demand outpaces capacity.

Customs Clearance at Destination

Peak season shipping also affects customs operations in destination countries.

During high-volume periods:

- Inspection queues lengthen

- Documentation review takes more time

- Tax assessment may be delayed

- Public holidays reduce processing throughput

A parcel held at customs during peak season is typically waiting in sequence, not under investigation.

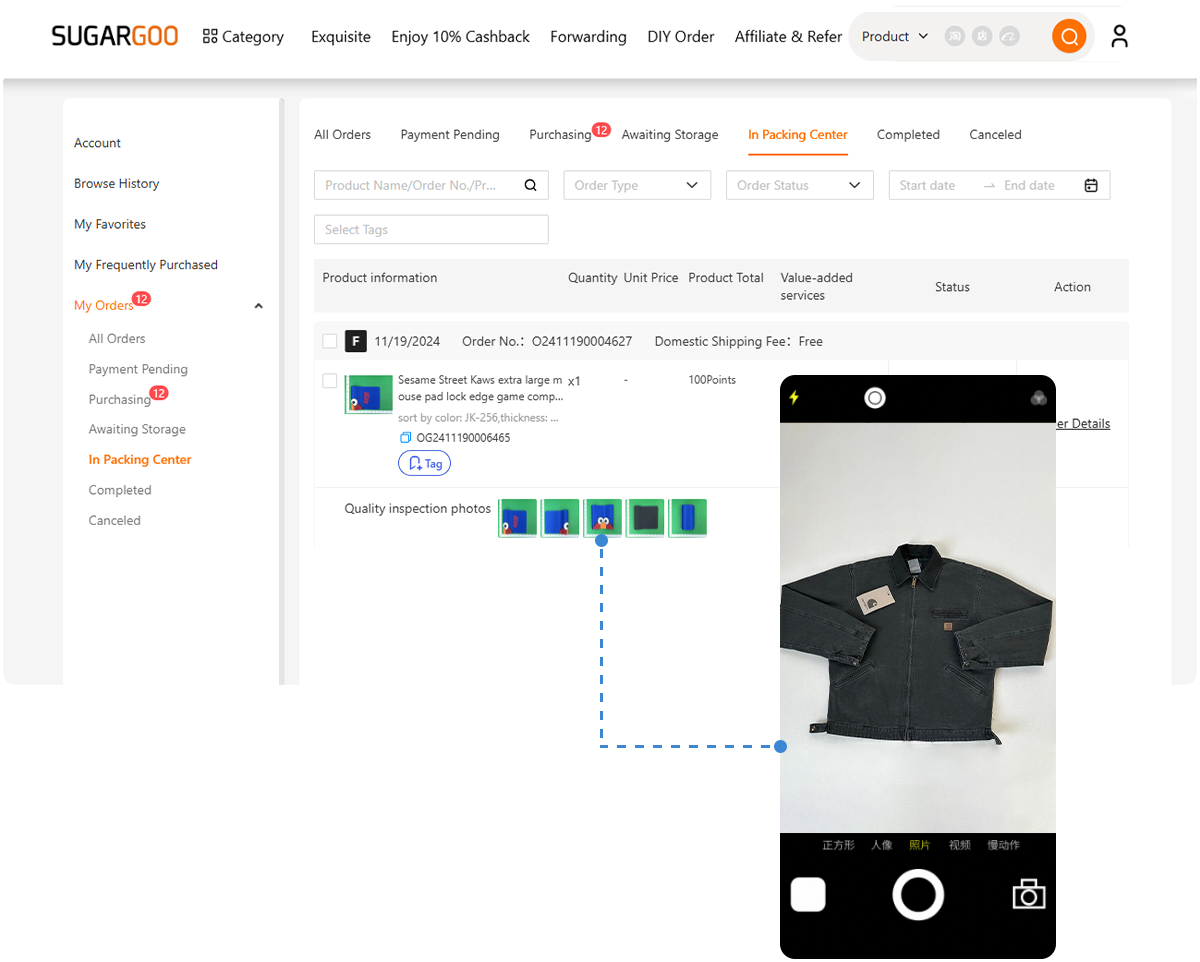

Local Delivery and Final Dispatch

After customs release, parcels enter local courier networks.

At this stage, peak season shipping can cause:

- Delayed sorting at local depots

- High delivery density per route

- Limited reattempt windows

- Slower updates in tracking systems

This explains why delivery may still take time even after arrival in the destination country.

Common Misinterpretations of Peak Season Shipping

Many delivery concerns during peak season shipping stem from incorrect assumptions.

Frequent misunderstandings include:

- Assuming missing tracking updates indicate loss

- Believing customs delays signal a problem

- Expecting peak season timelines to match off-season performance

- Treating all shipping methods as equally affected

In reality, most peak season shipping delays reflect normal backlog management.

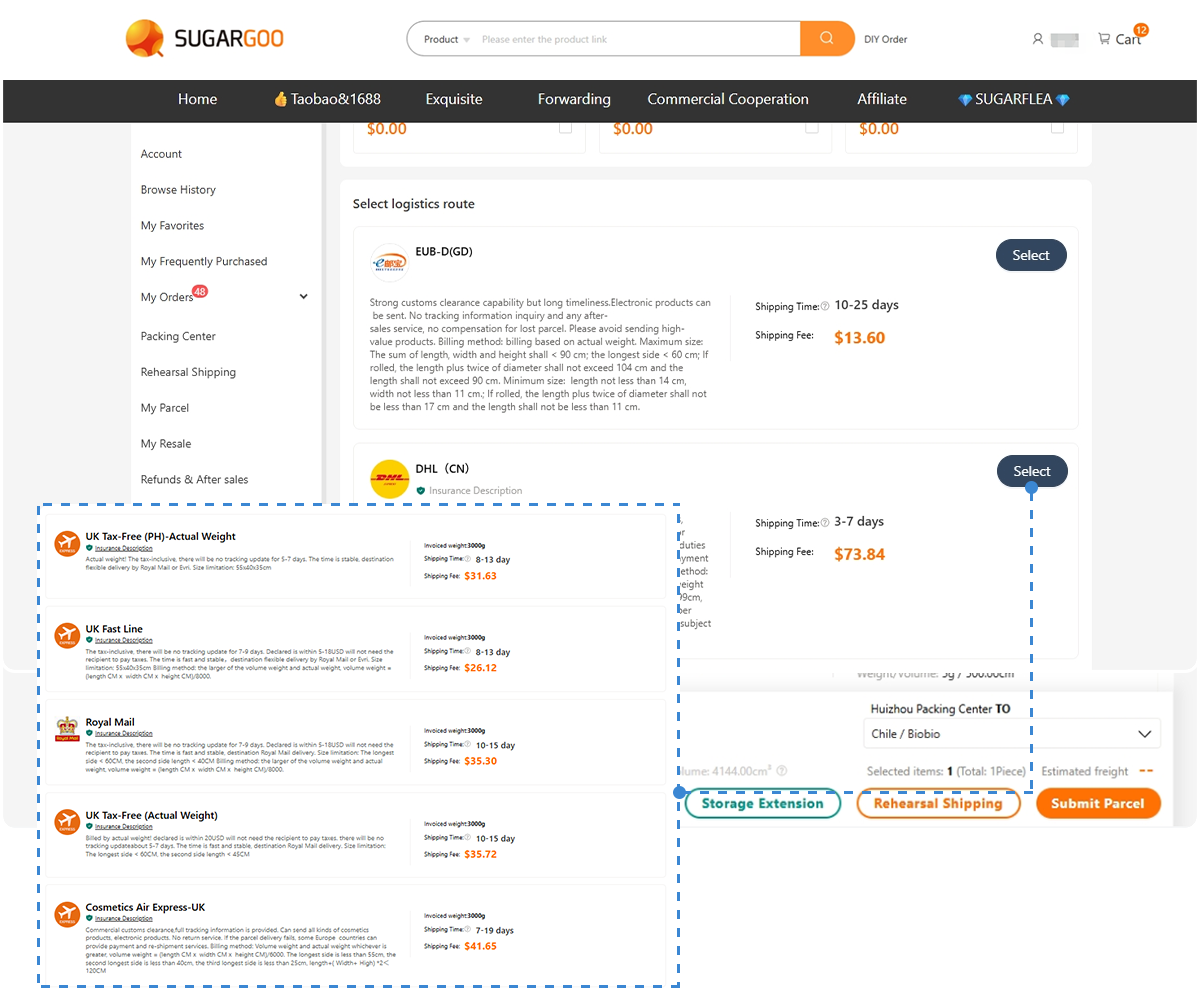

Which Shipping Options Are Most Affected?

Shipping performance varies significantly during peak season shipping.

General patterns include:

- Economy routes experiencing the longest extensions

- Express services remaining faster but less consistent

- Routes with limited capacity filling early

- Priority channels enforcing daily shipment limits

Flexibility becomes a key factor when choosing shipping during busy periods.

Additional Risks During Peak Season Shipping

Beyond timing delays, peak season shipping can introduce secondary challenges:

- Longer return and refund processing cycles

- Increased handling, raising the chance of minor damage

- Slower response times from logistics providers

- Extended compensation timelines

Awareness helps buyers plan accordingly.

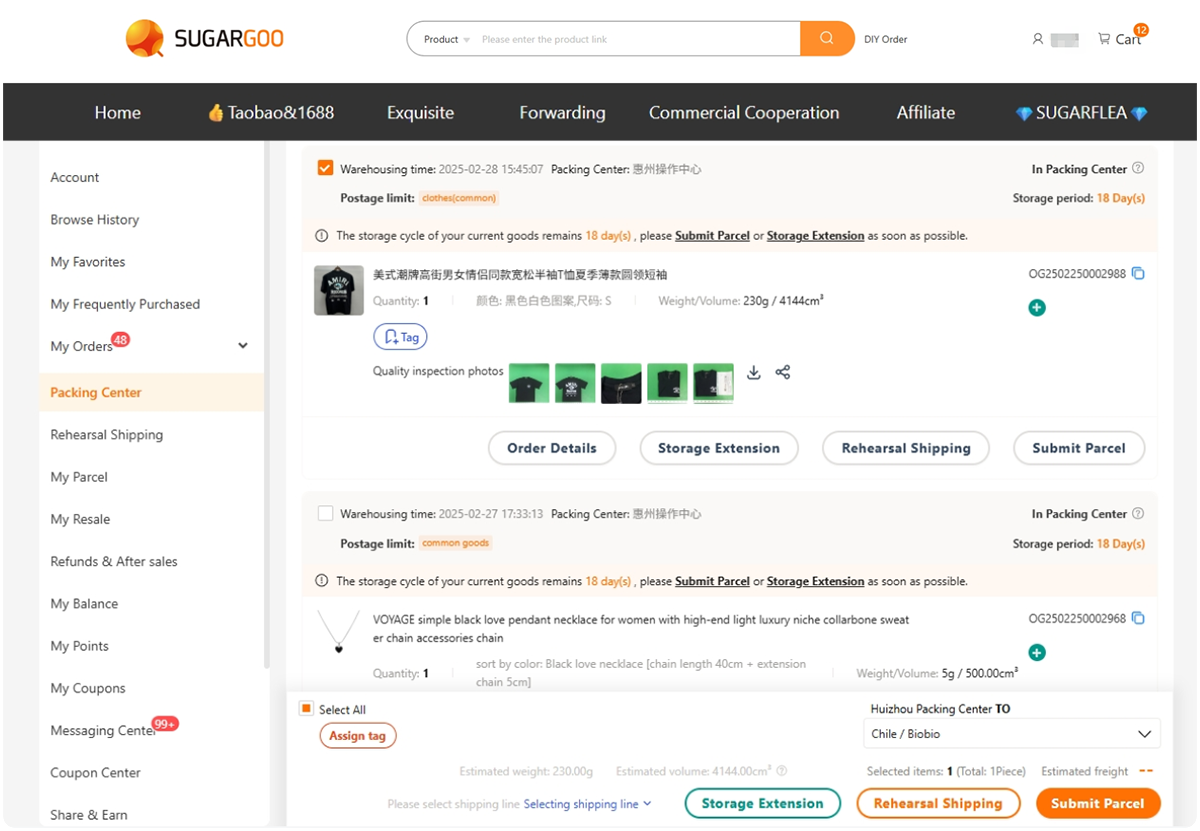

How Buyers Can Reduce Peak Season Shipping Uncertainty

While peak season shipping cannot be avoided entirely, certain actions can reduce uncertainty:

- Placing orders earlier than usual

- Avoiding fixed delivery deadlines during busy periods

- Choosing stability over the lowest-cost shipping option

- Managing consolidation carefully to prevent added delays

- Using protective packaging or insurance when appropriate

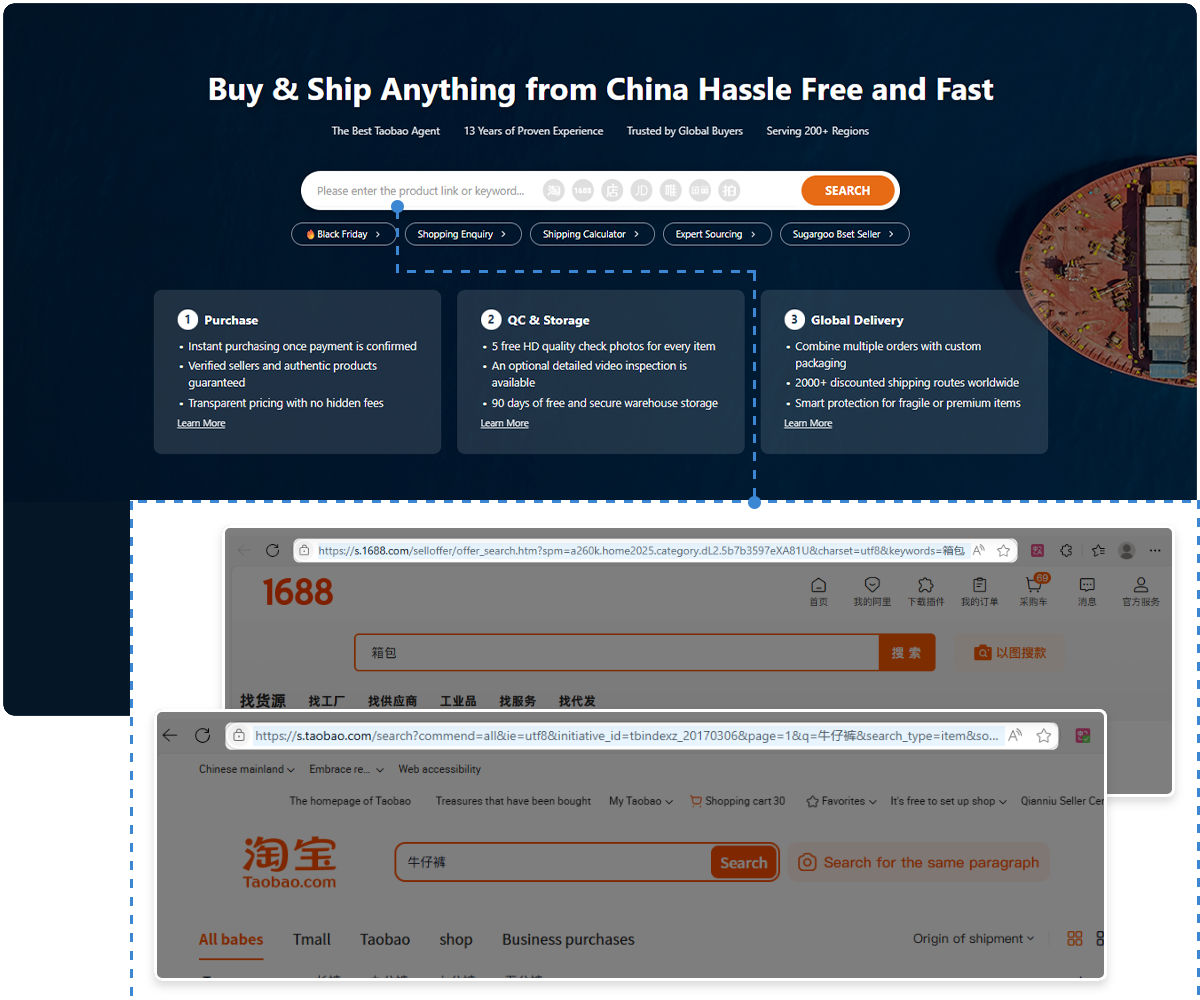

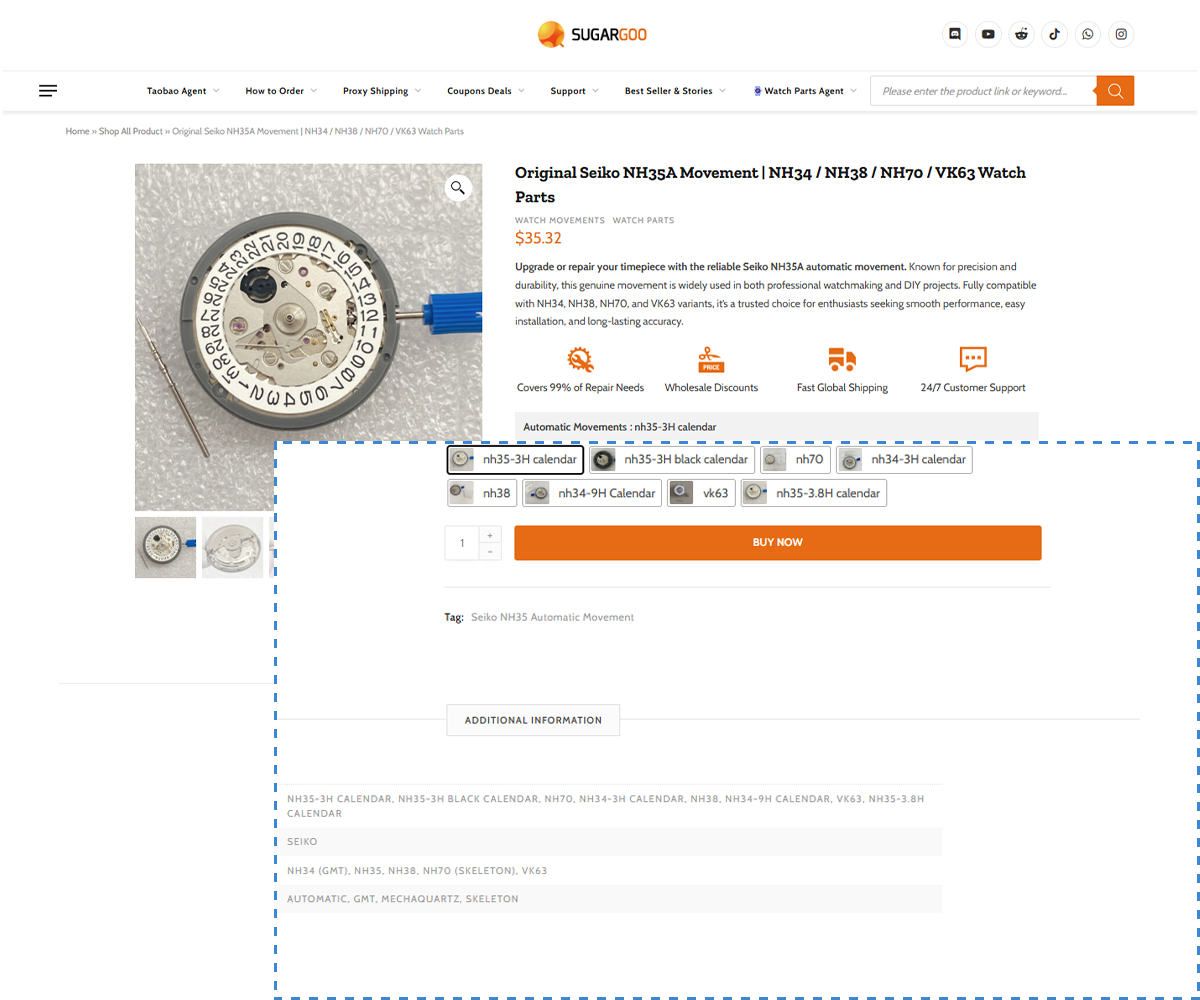

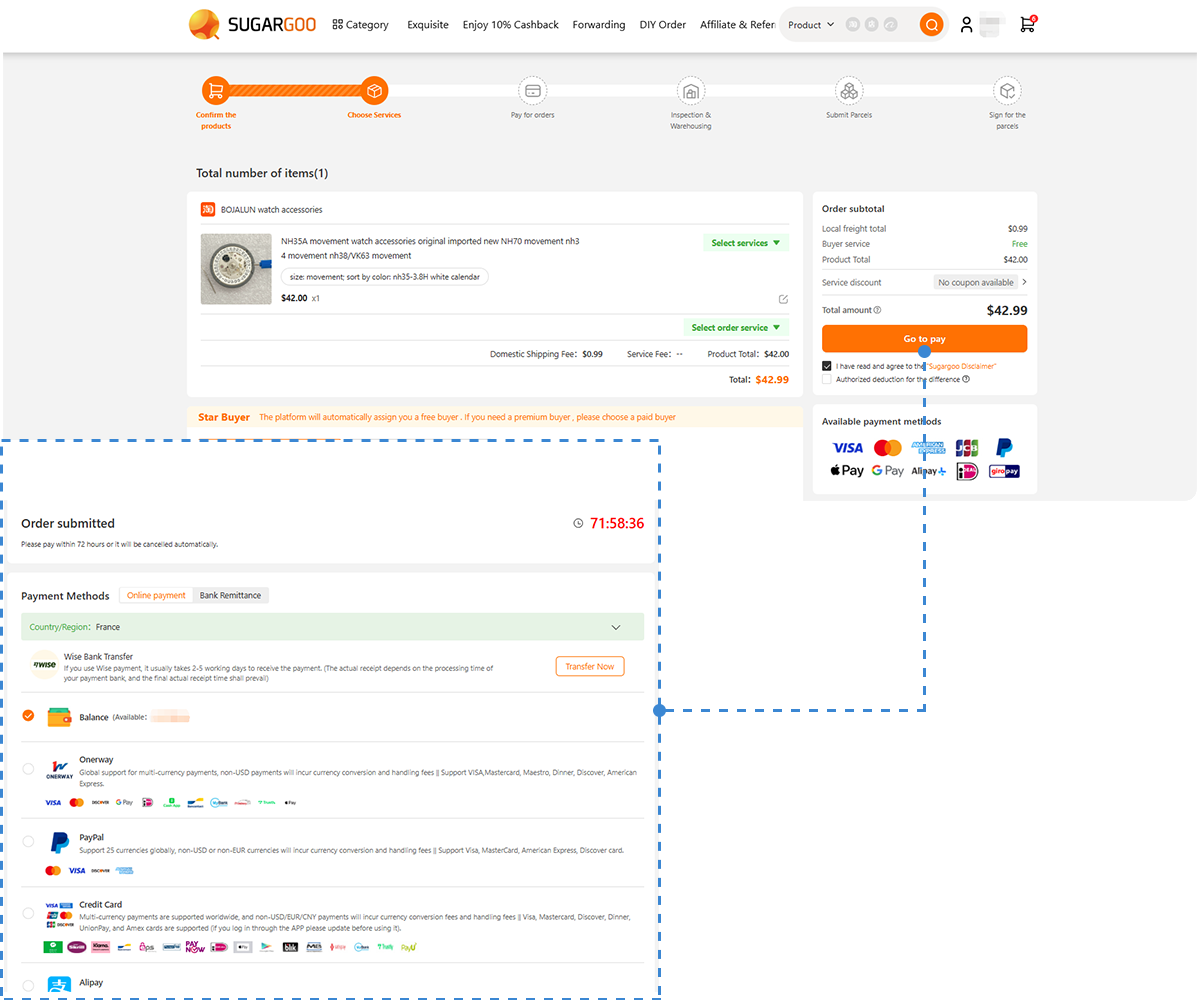

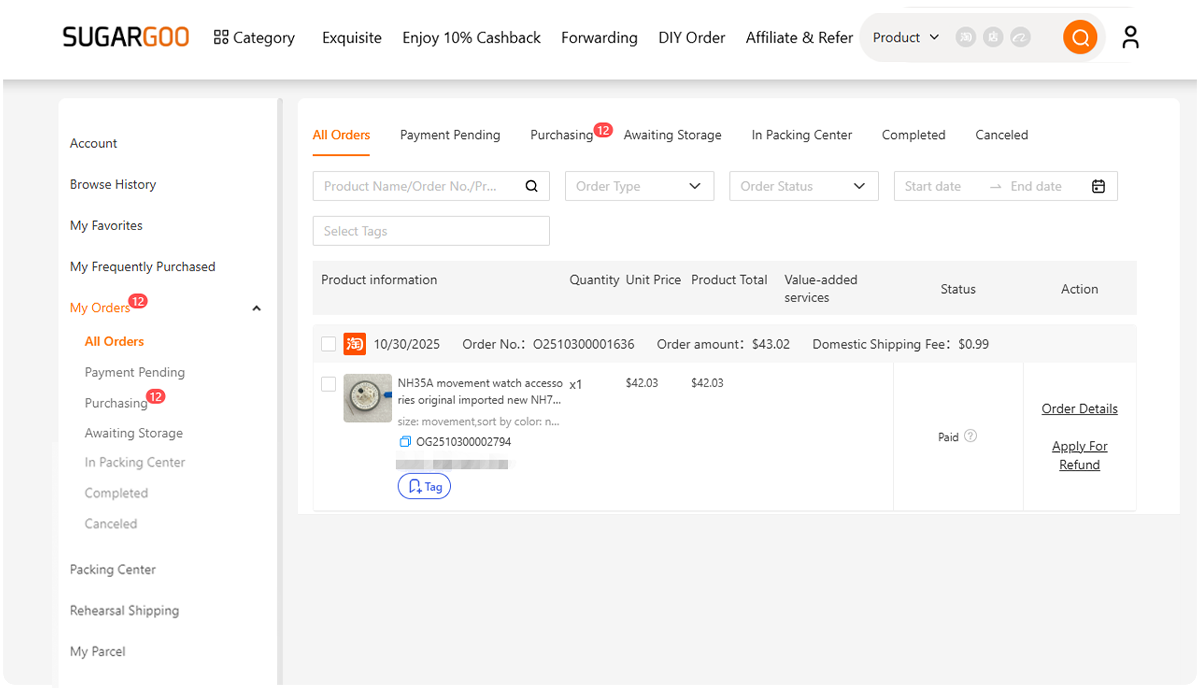

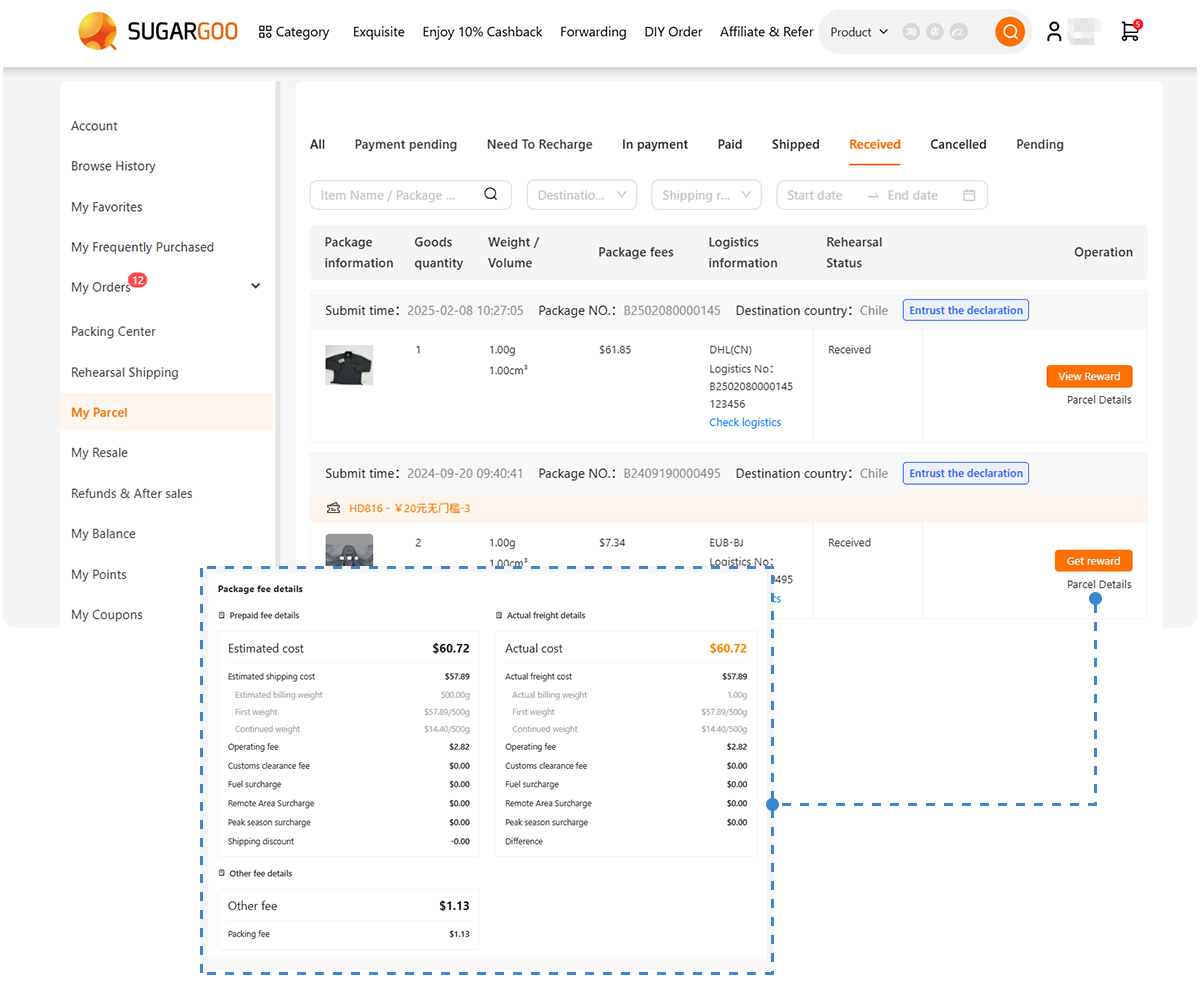

For buyers sourcing products from Chinese platforms, peak season shipping can be particularly complex. Working with a buying agent that offers multiple international shipping options—such as Sugargoo—can help manage these fluctuations. An experienced agent enables order consolidation, route comparison, warehouse visibility, and timing adjustments based on current congestion levels. Many services also include optional shipping insurance, reinforced packaging, and other value-added options that reduce risk during high-volume periods, when parcels are handled more frequently than usual.

This flexibility is especially valuable when standard shipping estimates become unreliable.

A Practical Peak Season Shipping Timeline

A shipment that normally arrives within 15-20 days may experience additional time during peak season shipping due to accumulated delays:

- Extra processing days at the warehouse

- Waiting time for export dispatch

- Extended international transit

- Longer customs and local delivery queues

Peak season shipping stretches delivery windows rather than stopping movement altogether.

Viewing Peak Season Shipping Realistically

Peak season shipping places sustained demand on global logistics networks from origin to destination. Longer delivery times during these periods are a predictable outcome of concentrated international demand, not a sign of failure.

Buyers who understand how peak season shipping operates can make better decisions, plan with more flexibility, and remain confident even when timelines extend.

Delays may be unavoidable during peak season shipping, but informed expectations make the process far easier to manage.