There’s something magical about a watchmaker’s bench. It’s not just a workspace — it’s a theater of precision. Every drawer, every tool has its purpose, each one telling a quiet story about patience, skill, and respect for mechanics.

If you’ve ever opened a caseback and seen the heartbeat of a movement, you already know: once you start working on watches, there’s no going back. The tools you choose define your experience — they can make the difference between frustration and satisfaction, between a broken pivot and a perfectly seated hand.

This is the ultimate toolkit checklist every modder, repairer, or aspiring horologist should know by heart.

Step One: Building the Foundation — Tools for Stability and Vision

Before you even touch a movement, you need a clean, stable environment. The best watchmakers in Switzerland will tell you: precision begins long before you pick up your first screwdriver.

1. The Work Surface

A clean, padded, lint-free mat is non-negotiable. It prevents parts from bouncing away, reduces scratches, and adds friction when working with delicate assemblies.

Choose a neutral color like light green or gray — it improves visibility under light and prevents eye strain.

2. The Light

Shadows are the enemy. Use a LED adjustable lamp with soft white light (around 5000K). Avoid harsh blue light; it distorts your sense of depth.

If you’re shooting photos or documenting your builds for forums or product pages, even lighting will make your work look professional.

3. The Loupe or Magnifier

Your eyes are your best tool. A 3x–5x loupe is enough for basic assembly, but a 10x helps for regulating escapements or inspecting balance pivots.

Try to keep both hands free — head-mounted magnifiers work best.

You can explore loupes and optical accessories under Watch Repair Tools — several come with anti-fog lenses and adjustable mounts.

Step Two: Precision in Motion — The Tools You’ll Use Every Day

Once your setup is ready, you move into the heart of the craft — the tools that bring movements to life.

4. Screwdriver Set

No other tool gets used more than the screwdriver. A proper watchmaker’s screwdriver set with hardened steel tips makes all the difference.

Cheap screwdrivers twist and chip easily, damaging screws or slipping onto the movement. Look for sets that include sizes 0.6mm to 2.5mm, color-coded for convenience.

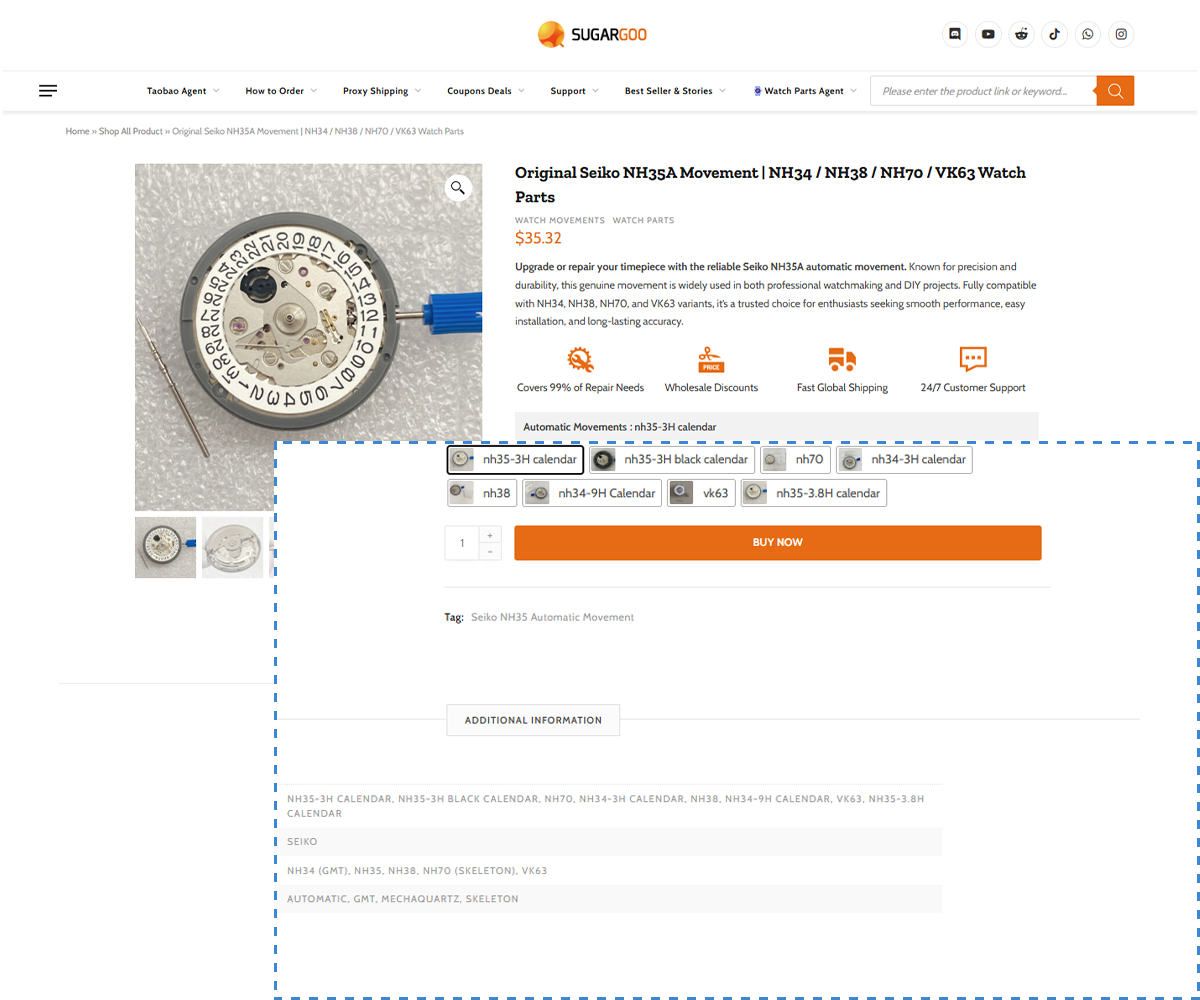

Store them vertically to prevent dulling the tips. You can find full kits under Watchmaker’s Toolkit Checklist or bundled with modding kits for NH35 builds.

5. Tweezers

The second most-used tool in watchmaking is the tweezer.

Get anti-magnetic stainless steel tweezers — cheap ones attract screws like magnets, creating chaos. A No. 2 or No. 3 pair handles larger parts, while No. 5 is for fine pivots or escapements.

Keep them clean; even fingerprints can rust the tips.

For modders, tweezers are essential when installing watch hands, movement clamps, or dial feet from Custom Watch Parts collections.

6. Movement Holder

The movement holder is the unsung hero. It keeps everything stable when working on dials, hands, or calendar parts.

An adjustable metal holder fits most calibers — from NH35 to ETA 2824 and ST36. Plastic ones are fine for beginners but wear out quickly.

You can browse adjustable versions under Watch Movement Holders — ideal for modding or full movement servicing.

7. Hand Remover and Hand Press Tools

Few steps are as nerve-wracking as installing or removing hands. The hand remover safely lifts them without scratching the dial. The hand press seats them back perfectly aligned and parallel.

Pressing unevenly can cause hands to rub or jam the second wheel. Always protect the dial with a plastic sheet before removal.

Find professional-grade tools at Watch Repair Tools — or learn the method in How to Align Watch Hands Perfectly Every Time.

Step Three: The Outer Shell — Working with Cases and Crystals

You’ve handled the heart; now let’s talk about the body. Changing cases or crystals requires the right leverage and touch.

8. Case Back Opener

There’s no shortcut here. A proper case back opener prevents the scratches and slips that ruin finishes.

Use a Jaxa wrench for screw-down backs or a friction ball for simpler designs. Always support the case on a rubber block to absorb torque.

A wide selection is available in Watch Case Back Opener and Watch Cases Replacement for different build types.

9. Spring Bar Tool

Essential for strap swaps or bracelet sizing. Choose one with sharp, replaceable tips — blunt tools scratch lugs easily.

It’s perfect for quick modding work like changing leather, rubber, or stainless steel straps found in Watch Straps.

If you’re new, see the guide How to Change Watch Straps with a Spring Bar Tool for a clean, safe process.

10. Crystal Press

For installing watch crystals or transparent case backs, a press provides even pressure to avoid cracking or misalignment.

A simple hand press with nylon dies is enough for most hobbyists. Use slow, controlled force — if it doesn’t fit easily, stop and realign.

Compatible sapphire crystals can be found at Watch Crystals Sapphire for both Seiko and ETA builds.

Step Four: Clean, Oil, and Maintain — The Tools of Respect

Every movement deserves maintenance. Keeping your tools and components clean ensures your watches last for decades.

11. Rodico and Dust Blower

Rodico is a sticky, reusable putty that removes dust, oils, and fingerprints. Pair it with a dust blower to clear tiny particles before sealing a case.

It’s especially helpful before you close the back or install sapphire domes.

12. Watch Oils and Lubricants

Every pivot needs lubrication — not too much, not too little. Use fine synthetic watch oils, never general-purpose grease.

Different viscosities suit different parts:

- Thin oils for escapements

- Medium for train wheels

- Thick for mainsprings

Learn more from Watch Oils and Lubricants Explained — a complete beginner’s guide to proper care.

13. Cleaning Cloths and Storage Trays

Always keep a few microfiber cloths for wiping crystals, cases, and tool handles. Use anti-static movement trays to prevent losing screws.

These essentials are available under Watch Accessories and Watch Cleaning Cloths.

Step Five: Specialty Tools for Modders

If you’re into customization and NH35 or ETA builds, a few extra tools make the experience smoother.

- Bezel removal tools — for swapping inserts or rotating bezels.

- Crown stem cutter — for precise fitment.

- Dial protector sheets — to avoid marks when handling hands.

- Case clamps and screws — to secure movements in custom cases.

- Timegrapher or timing app — to regulate your watch accurately.

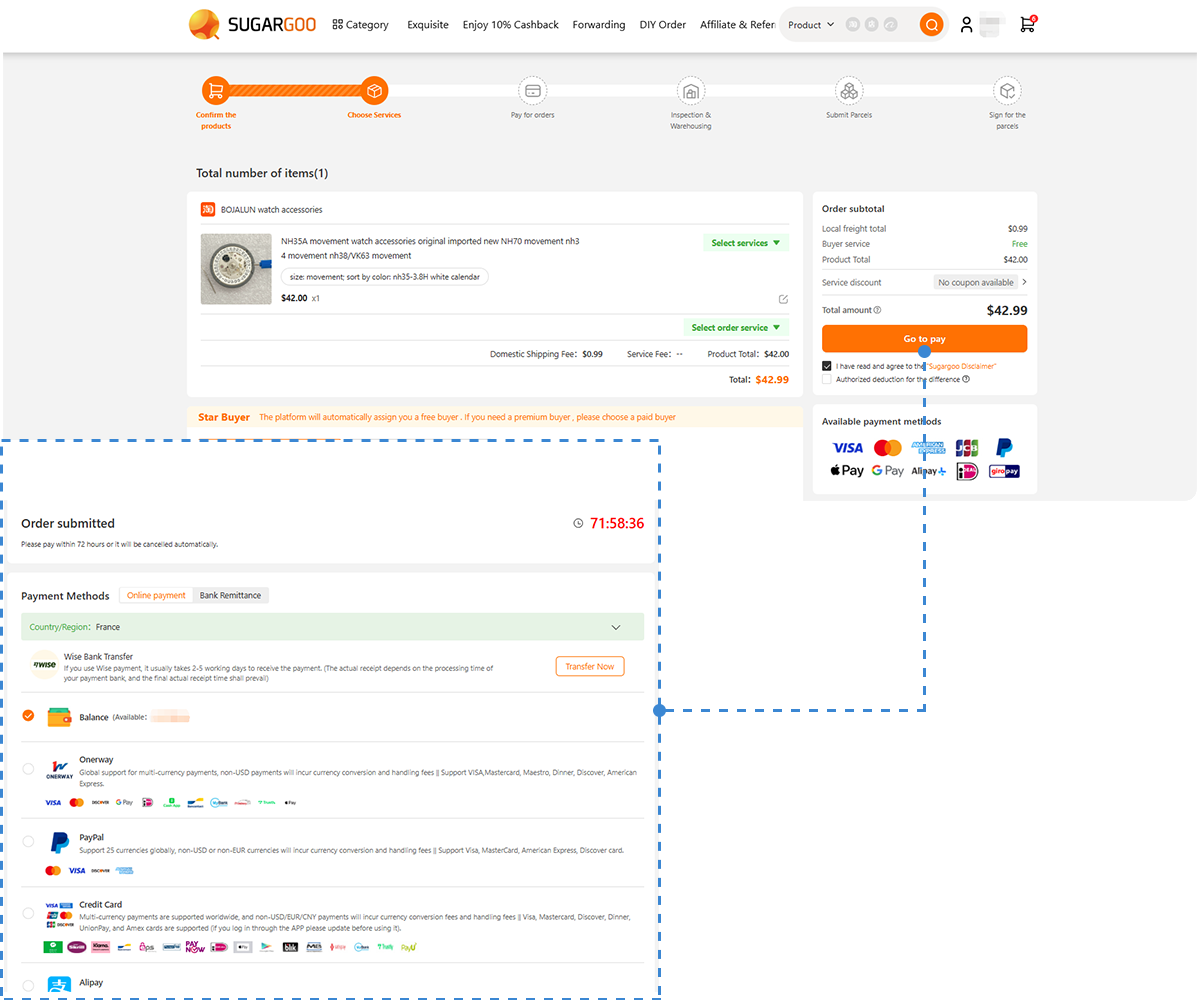

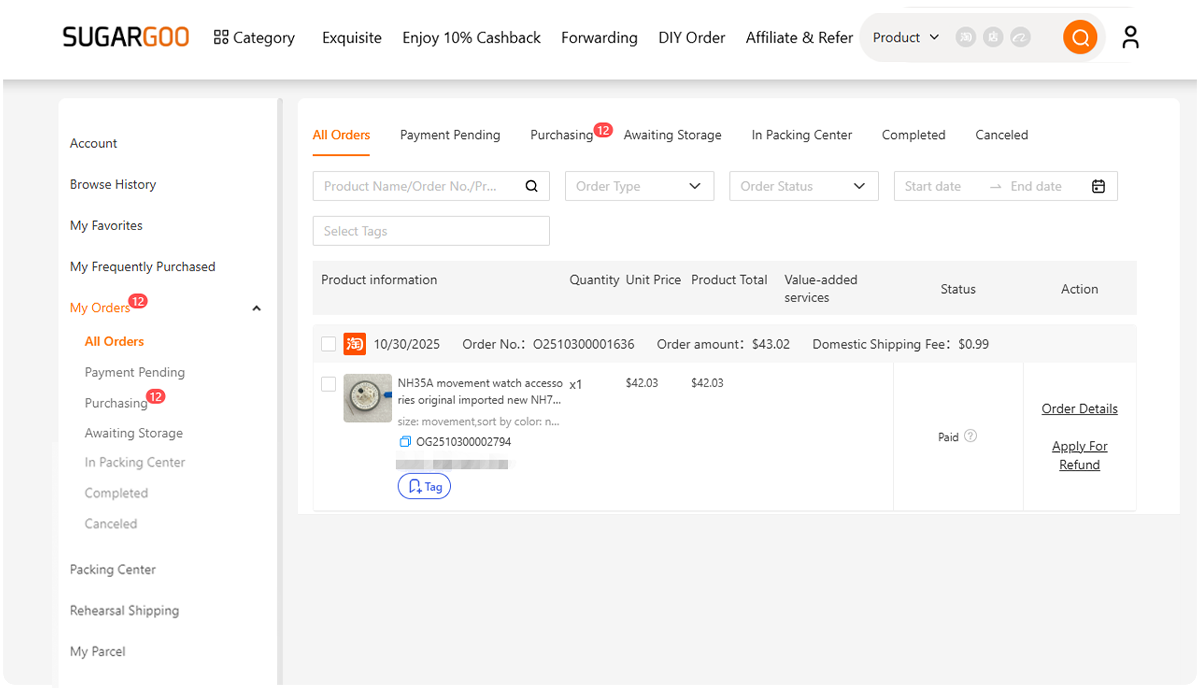

All of these can be found in the Sugargoo Watch Repair Tools collection or bundled into DIY modding kits.

Step Six: The Mindset — Why Tools Matter Beyond Function

The longer you work with watches, the more you realize: tools aren’t just for doing — they’re for becoming.

They train your patience, sharpen your eye, and reward discipline. A bent screwdriver teaches focus. A lost screw teaches calm.

Each tool has its own lesson.

And when you finally sit down to assemble a movement, the hum of your lamp, the click of your tweezers, and the sweep of your loupe all become part of the same rhythm — the rhythm of watchmaking itself.

Step Seven: Building Your Toolkit Over Time

Don’t rush to buy everything at once. Start small, learn your process, and let your tools evolve with your skills.

Begin with:

- Screwdrivers

- Tweezers

- Spring bar tool

- Loupe

- Movement holder

Then upgrade as your builds become more complex. Quality tools aren’t just expenses — they’re investments in accuracy and joy.

You’ll find everything — from entry-level kits to professional setups — under Watchmaker’s Toolkit Checklist and Watch Repair Tools on Sugargoo.

Final Thoughts

Every tool in a watchmaker’s kit is a bridge between the mechanical and the human. They don’t just fix watches — they teach you how to move slower, see closer, and create something that lasts.

A proper toolkit isn’t just a checklist; it’s a philosophy of respect for craftsmanship. Because when you hold a watch movement steady under light, adjust its heartbeat, and seal it back into the case — you’re not repairing a watch. You’re restoring time itself.

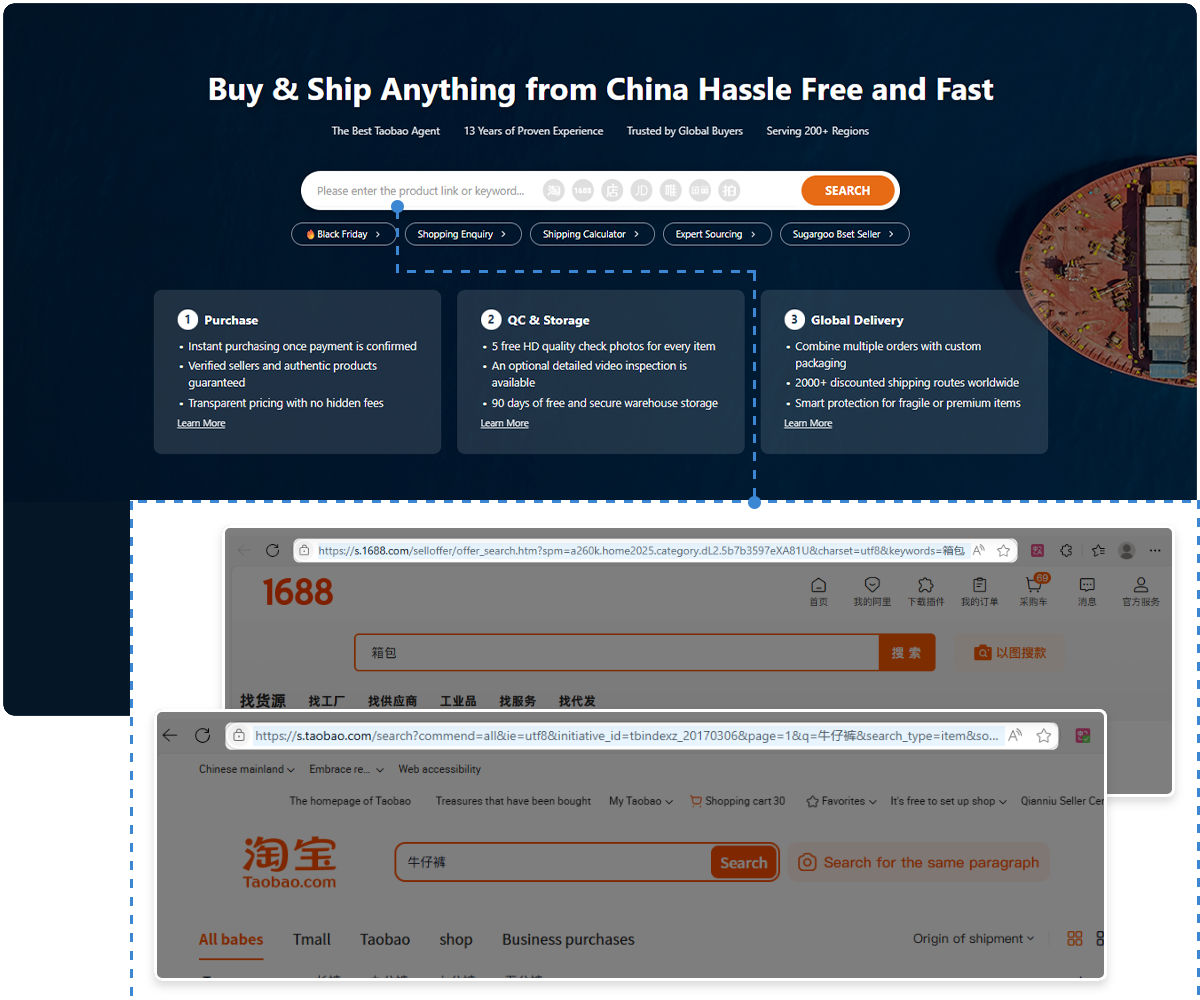

Start your journey with Sugargoo’s Watch Parts Collection or dive deeper with The Art of Modding: Building a Watch from Scratch.