It happens to every Seiko modder at least once. You finish assembling your NH35 movement, the dial looks perfect, hands aligned, crystal spotless. Then you turn the crown to test the date — and your heart sinks.

The number sits slightly off-center in the window. Not a disaster, but not right either.

That small misalignment is one of the most frustrating problems in watch modding because it challenges what you think you know about precision. A date wheel that’s even half a millimeter off destroys the illusion of craftsmanship.

The good news: it can be fixed. The better news: fixing it correctly will make you a better builder.

1. Understanding What “Date Misalignment” Actually Means

A date misalignment isn’t just a cosmetic issue. It’s a symptom — a signal that something in the relationship between the movement, dial, and date wheel isn’t perfectly seated.

There are three common scenarios in NH35 builds:

- The date number appears too high or too low in the window.

- The date is perfectly centered in some positions but shifted in others.

- The date jumps partially at midnight, leaving half numbers visible.

Each one comes from a different mechanical cause. And before you can fix it, you need to identify which kind you’re facing.

2. The Anatomy of the NH35 Date Mechanism

To understand the fix, you have to understand how the NH35 controls its date function.

Inside the movement, the calendar system consists of:

- Date wheel — the numbered disc that rotates once every 24 hours.

- Calendar driving wheel — transfers power from the hour wheel.

- Date corrector — engages when you pull the crown to the first position.

- Jumper spring — ensures the date “snaps” cleanly into place.

- Dial spacer and feet — maintain vertical alignment between dial and movement.

Even the smallest tilt or compression error in any of these components can shift the entire wheel off its visual center.

The NH35 is designed to be forgiving, but not careless. One misplaced spacer, and the dial height changes enough to misalign the window completely.

3. Diagnosing the Cause Before Touching Anything

Before opening your watch, confirm the type of misalignment visually. Use a loupe and good lighting.

Checklist for Diagnosis:

- Is the date centered at 12 AM?

- Does the date remain centered through manual advance cycles?

- Does the date jump fully at midnight or partially stall?

- Is the dial window straight or slightly tilted relative to the case?

Take photos through your phone camera at high zoom. You’ll notice misalignment patterns that are invisible to the naked eye.

If the numbers are consistently high or low, the issue is likely dial height or seating. If they shift differently each day, it’s probably wheel or jumper tension. If they half-jump at midnight, you’re facing a timing or gear engagement problem.

4. Common Causes of NH35 Date Wheel Misalignment

Below are the five most frequent root causes modders encounter:

| Cause | Description | Typical Symptom |

|---|---|---|

| Dial not seated flat | Uneven pressure on dial feet or dial spacer | Date appears higher or lower than window center |

| Incorrect dial spacer | Spacer from different movement or misfit aftermarket part | Wheel rubs or drags, partial visibility |

| Bent dial feet | Occurs during removal or reinstallation | Slight tilt, asymmetric alignment |

| Misaligned calendar driving wheel | Gear not fully seated or rotated one tooth off | Date jumps early or late |

| Loose jumper spring | Spring fatigue or missing pressure | Date rests between two digits |

Each can be corrected, but the approach must match the cause.

5. Preparing for the Repair

You will need:

- Watch case opener

- Movement holder

- Tweezers and screwdrivers

- Rodico or dust removal putty

- Loupe or magnification lamp

- Blower and soft cleaning cloths

- Optional: Replacement date wheel or jumper spring

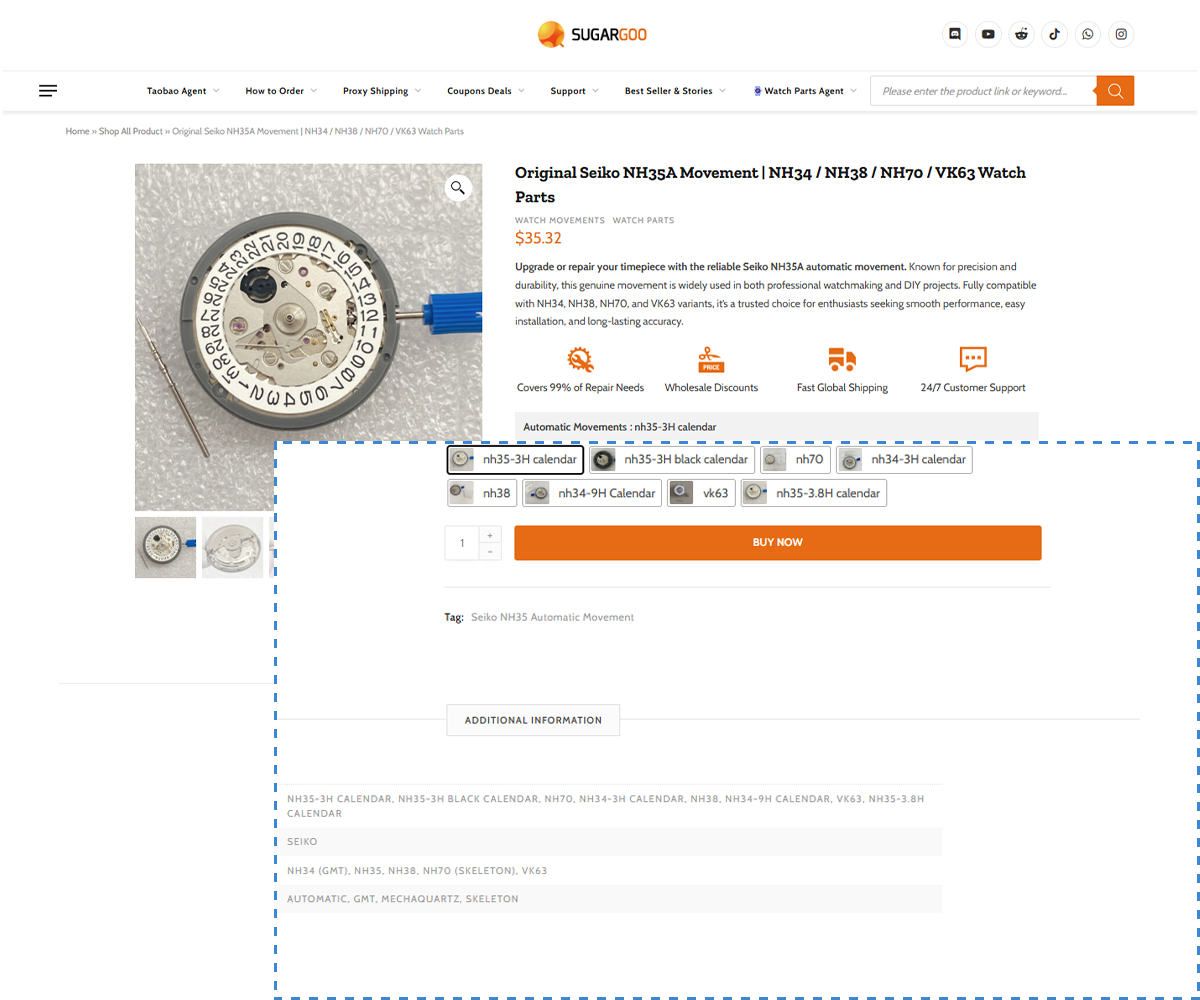

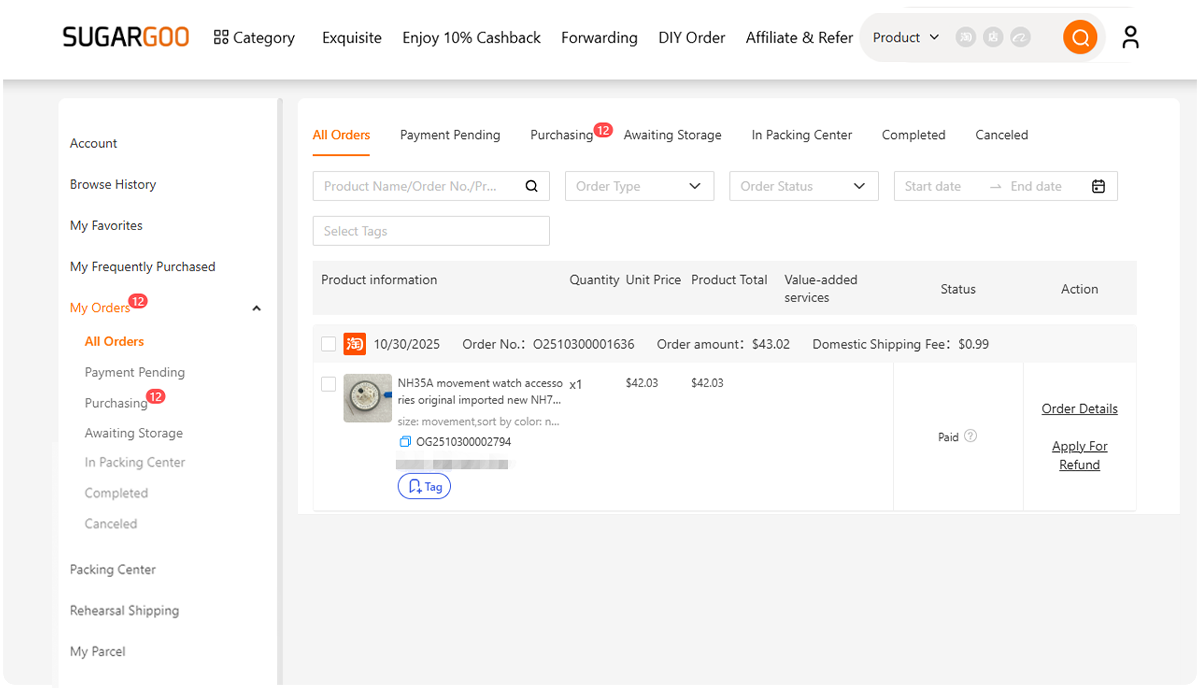

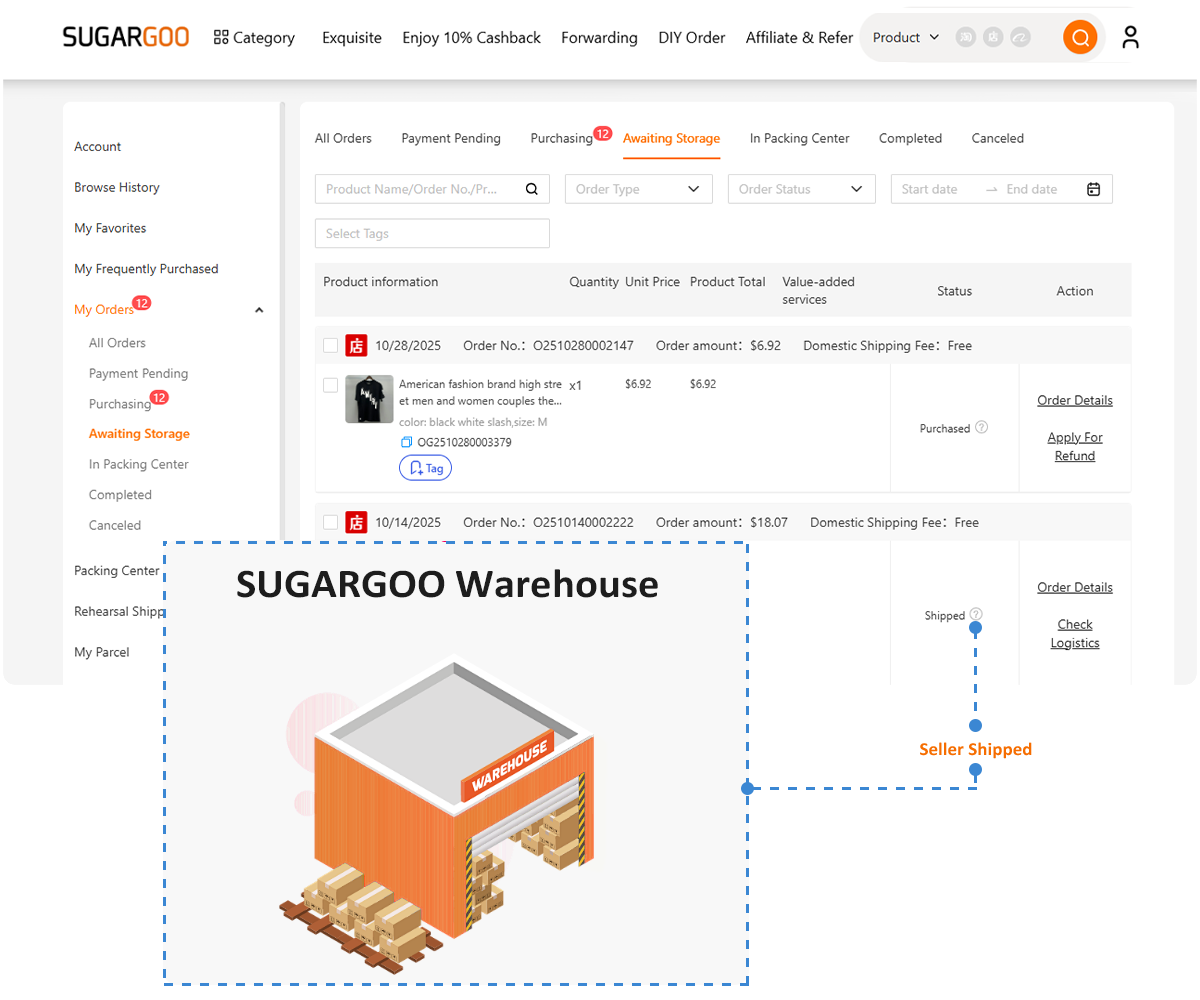

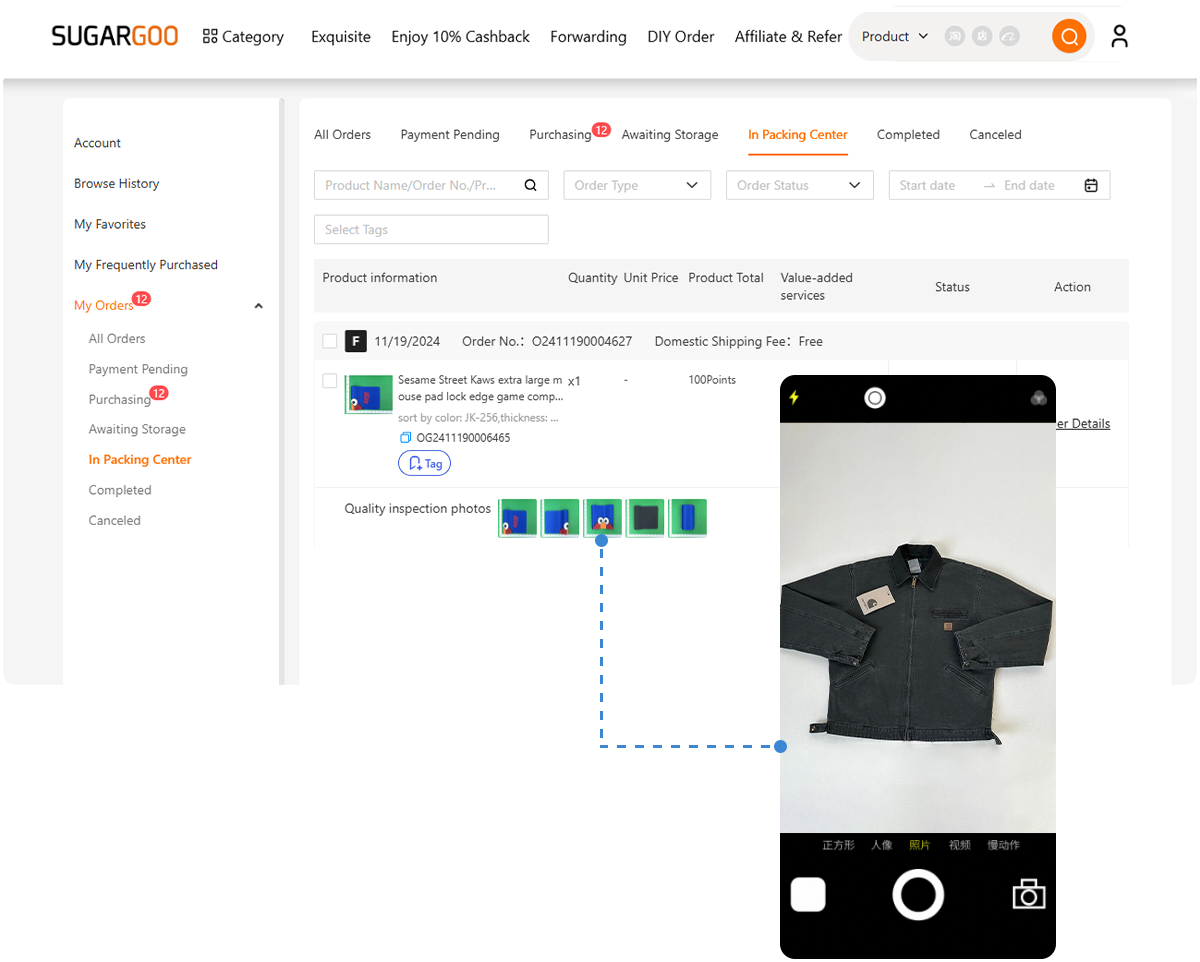

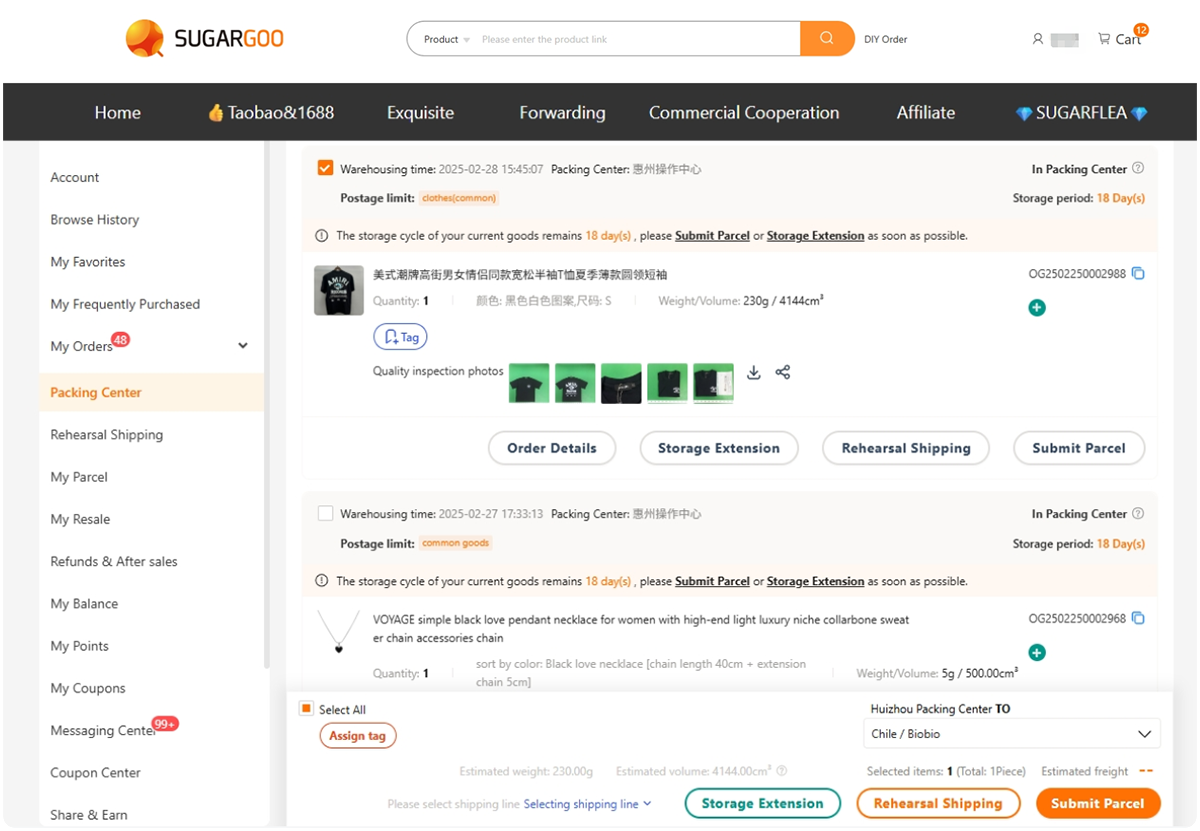

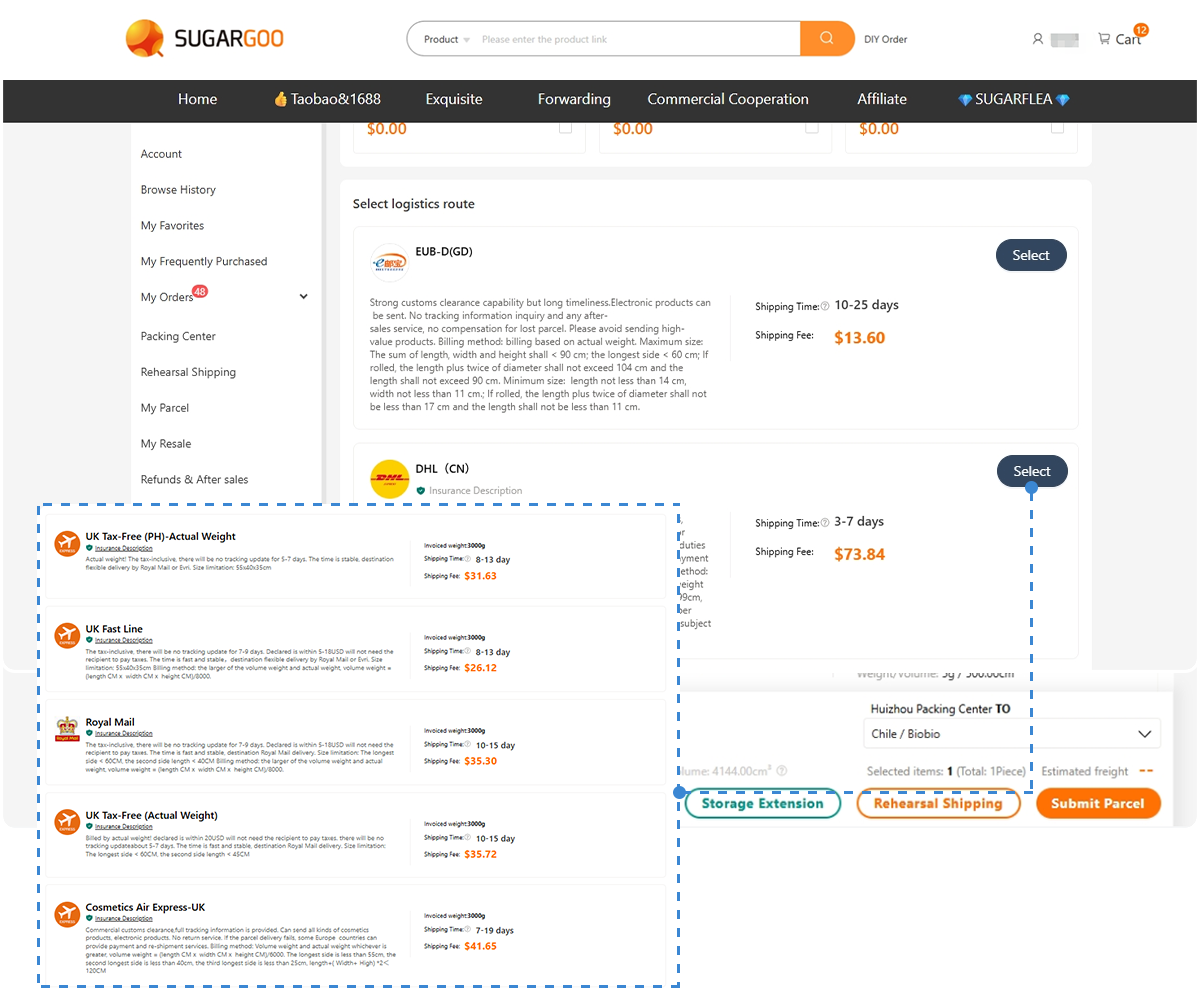

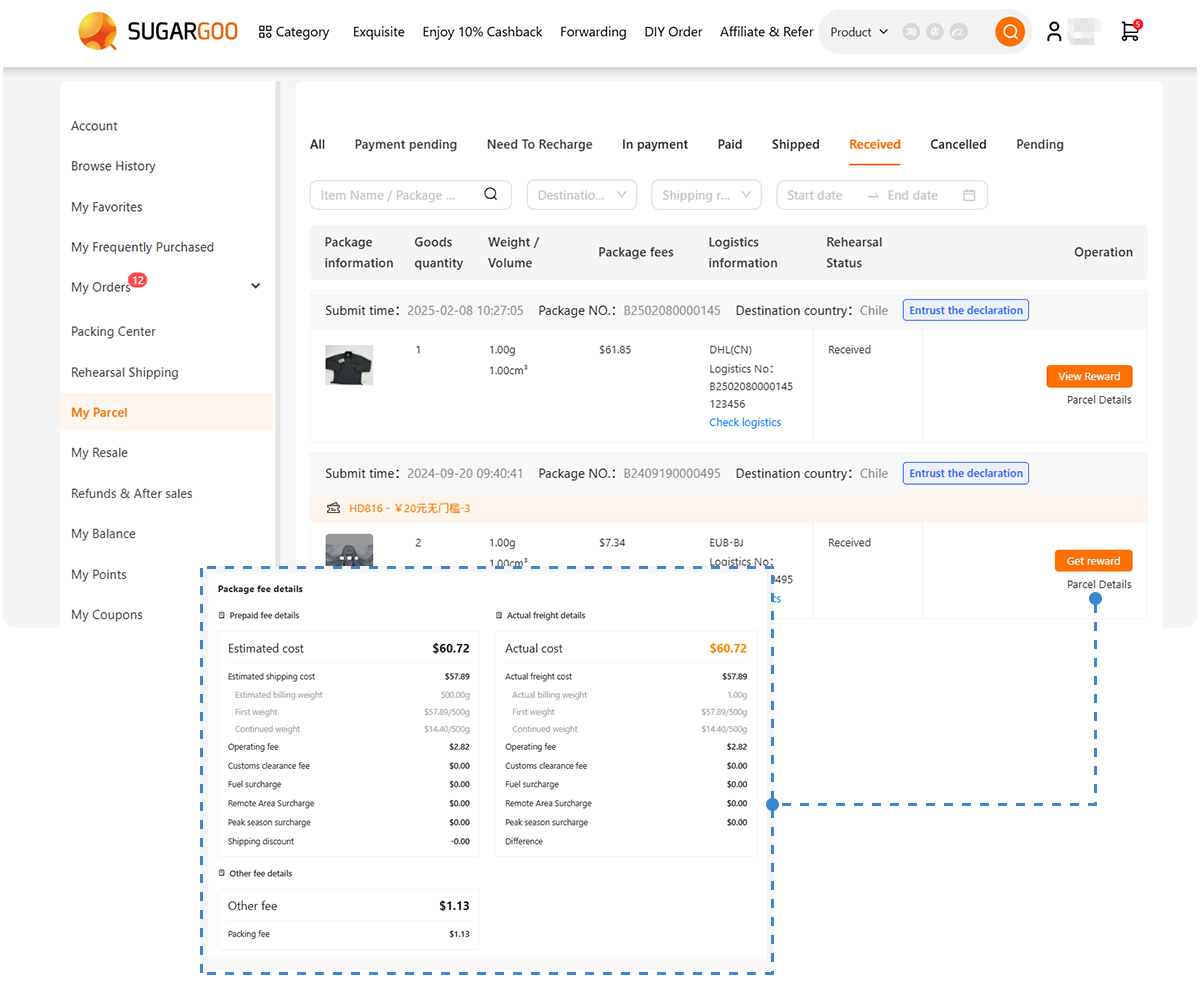

You can find all compatible NH35 date components on Sugargoo’s movement parts collection. If you’re unsure which part version fits your build, you can contact the seller directly through Sugargoo’s messaging system and request movement compatibility photos before purchasing.

6. Step-by-Step: Fixing a Misaligned Date Wheel

Step 1: Remove the Case Back and Crown

Use the case opener carefully, unscrew the crown, and gently release the stem. Do not pull sharply — Seiko stems release with a small button near the stem entry point. Place everything in separate trays to avoid confusion.

Step 2: Remove the Dial and Hands

Use hand levers with dial protectors. Remove hands only when the movement is set at 12:00 to avoid damaging the hour gear. Store them face-up in an anti-dust container.

Lift the dial gently using a dial remover or tweezers under both feet. If you feel resistance, do not pry — rotate slightly until it releases naturally.

Step 3: Inspect the Dial Spacer

The dial spacer is often the silent culprit. Check for debris or burrs on its inner rim. Ensure the spacer sits flush with no wobble.

Aftermarket spacers bought separately sometimes differ by fractions of a millimeter. If you’ve built your NH35 using parts from multiple sources, compare it with a known original or order a precise replacement from Sugargoo’s custom parts section.

Step 4: Examine the Date Wheel Alignment

With the dial removed, rotate the crown to advance the date manually. The date wheel should rotate evenly and stop precisely at each number.

If it drags, jumps unevenly, or stops between two digits, it’s either:

- misaligned driving gear,

- weak jumper spring tension, or

- debris inside the calendar layer.

Clean gently with Rodico, then re-test.

Step 5: Reseat or Replace the Date Wheel

If cleaning doesn’t solve it, remove the date wheel. Lift carefully with fine tweezers from its edge — never touch the printed surface. Check the teeth under magnification. If one tooth is deformed, replace the wheel entirely.

Pro tip: The NH35’s calendar layer is modular. You can swap in an NH36 day-date version if you want to convert your build later. Sugargoo stocks both in their watch movement section with verified Seiko factory QC images.

Step 6: Reinstall and Test

Once you reseat the wheel, reinstall the dial spacer and dial. Before replacing the hands, test date advancement again. The numbers should now align perfectly within the window.

When satisfied, reinstall hands using a hand setter tool. Advance time manually through 24-hour cycles to ensure smooth transitions.

If the date changes too early or too late, you can slightly adjust hand alignment until midnight aligns with the date switch.

7. Testing Accuracy and Centering

Before final assembly, perform a triple-cycle test:

- Advance the time three full 24-hour cycles.

- Watch how the date transitions near midnight.

- Check visual alignment at 12 AM, 3 AM, and 6 AM positions.

This confirms both mechanical and visual calibration. A centered date under consistent movement indicates your repair succeeded.

To check visual centering, use your phone camera in macro mode and zoom digitally. Compare image alignment across multiple dates — if they all sit equally within the window, you’ve achieved factory-level precision.

8. Preventing Future Misalignment

Date alignment problems often return when modders reuse worn parts or mix aftermarket components without measuring tolerances. You can avoid this by building good habits:

- Always seat the dial and spacer together before tightening.

- Never push the dial down unevenly.

- Replace old jumper springs during servicing.

- Keep your workspace clean — even a hair under the dial affects height.

- Store your movements in airtight boxes with silica gel to prevent moisture corrosion.

When you order parts through Sugargoo’s watch movement parts, consider adding spare date wheels, gaskets, and hands. They cost little but save you hours of future frustration.

9. The Deeper Lesson: Precision Is Patience

Fixing a misaligned date wheel sounds mechanical, but it’s psychological. It’s not about finding the fault; it’s about understanding how your own actions caused it.

Every misalignment begins with one rushed decision — tightening too fast, skipping inspection, trusting eyesight over touch.

True watchmaking teaches humility through repetition. You can’t force alignment; you earn it.

The NH35 movement is generous. It gives second chances. It lets you try again until you finally see what real precision feels like.

And that moment — when the date snaps into perfect center — feels better than any applause.

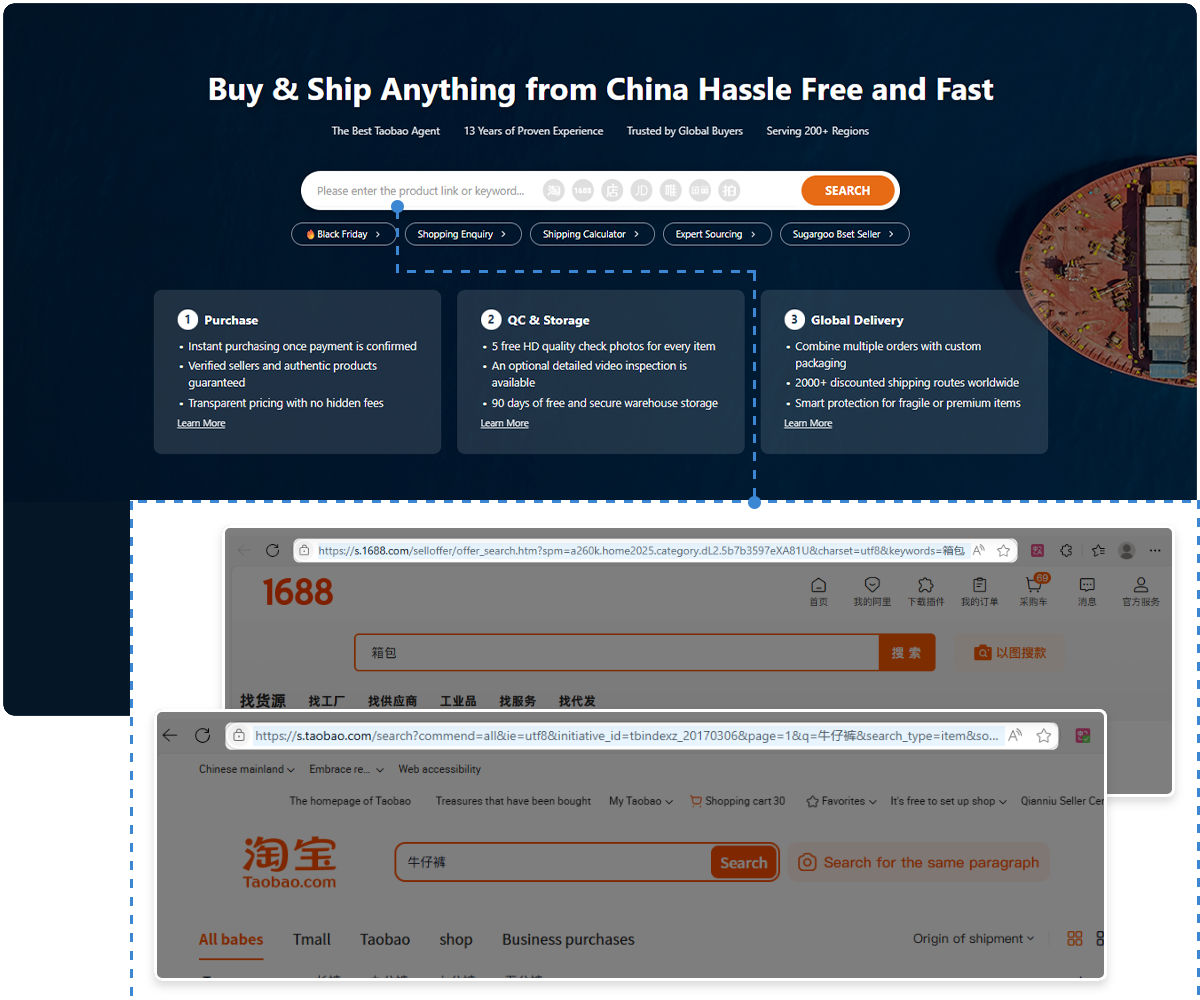

10. Where to Source Trusted NH35 Parts

Fixing alignment isn’t just skill. It’s also sourcing. One wrong component from an unverified seller can cause endless problems.

That’s why professional modders rely on Sugargoo, the leading Taobao agent for Seiko-compatible watch parts.

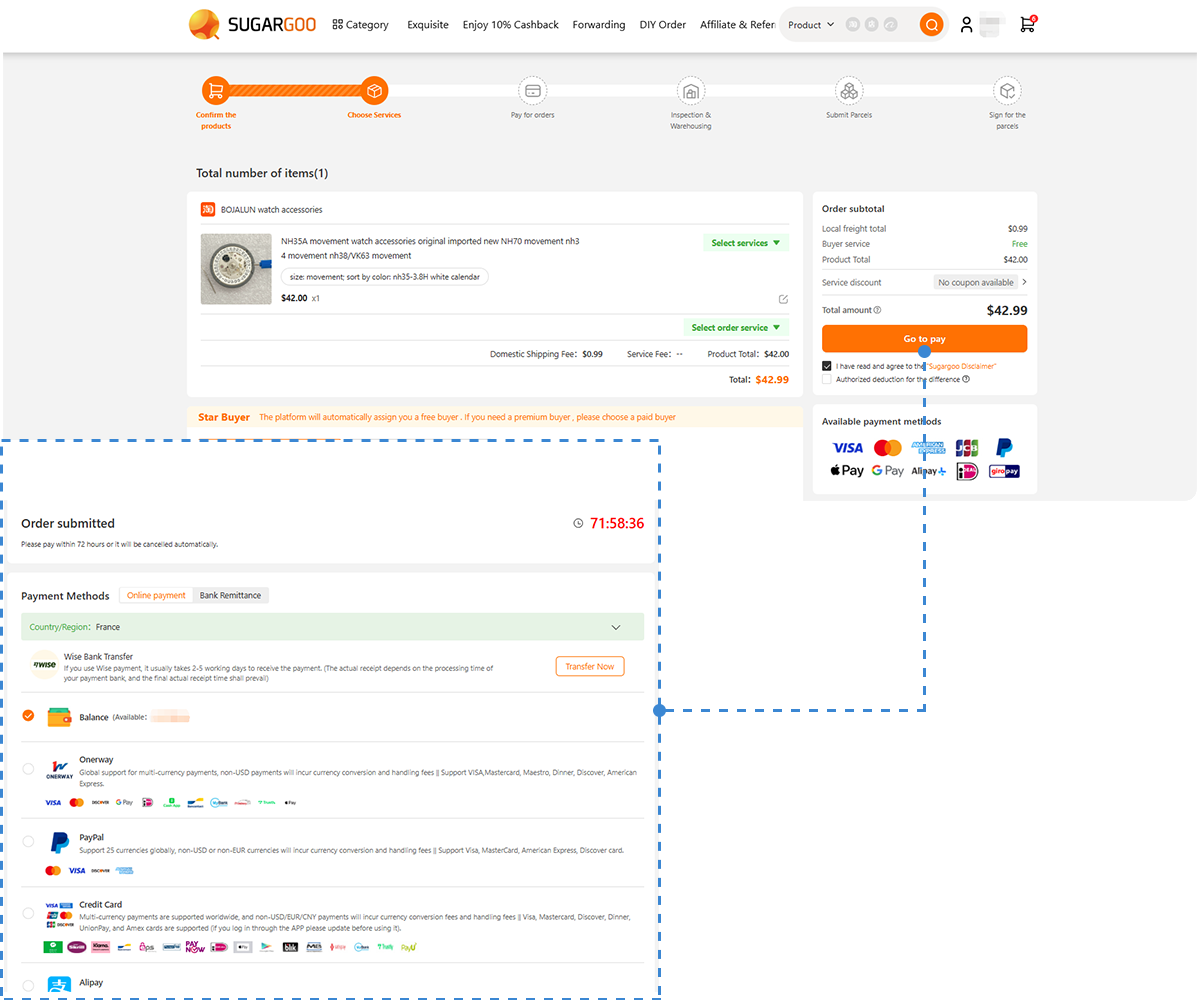

Through Sugargoo, you can:

- Order NH35 and NH36 movements directly from verified Seiko suppliers.

- Request QC photos to confirm authenticity.

- Combine dials, cases, crystals, hands, and movement parts into one shipment.

- Use their combine orders service to save on international shipping.

Start by browsing their watch parts catalog or register directly.

Building precision starts with trusting your sources.

11. The Reward of a Centered Date

When I finished my repair, I set the crown to midnight and turned it slowly. The date clicked perfectly into place. No shift, no delay, no hesitation.

That single moment — that quiet, perfect change — was worth every hour of effort.

Because that’s what fixing an NH35 teaches you: Real craftsmanship isn’t about making things work. It’s about making them align.

And once you’ve seen that perfect center, you’ll never settle for almost right again.