If you’ve ever tried changing your own watch strap, you probably remember the sound — that faint click, followed by a deep sigh of relief. Or maybe the other sound — a scratch, followed by silence and regret.

Either way, that first strap change is where most watch modders truly begin.

People think building or modifying a watch starts with movements or cases. It doesn’t. It starts with a small metal rod — the spring bar — and your courage to take something apart for the first time.

And that’s where mistakes are born.

Because the moment you hold that spring bar tool and stare at your precious Seiko or NH35 custom build, your hands realize how fragile time really is.

Let’s talk about those mistakes. The ones every builder makes, the ones that hurt a little, and the ones that — if you listen — teach you more about craftsmanship than success ever will.

Mistake #1: Choosing the Wrong Strap Width

I once saw a beginner force a 22mm strap onto a 20mm case. It fit — kind of. Until it didn’t.

That tiny mismatch (just 2 millimeters) doesn’t sound like much, but it’s enough to bend spring bars, warp lugs, and ruin symmetry. And nothing ruins a watch faster than tension in the wrong place.

How to Check the Right Size

Measure lug-to-lug width using calipers (or just a ruler if you’re gentle).

Most Seiko NH35 and SKX-style cases are 20mm or 22mm, but always check.

The end of your strap should align flush with the lugs — no gaps, no pressure.

If you’re unsure, look through Sugargoo’s watch straps collection. Each listing mentions compatible lug widths and strap curvature, perfect for matching to your watch cases or custom builds.

Why This Matters

Wrong width doesn’t just look off. It changes how your watch wears. Too tight? You’ll stress the lugs and scratch the case. Too loose? The watch flops around like it’s wearing you.

Remember, straps are like shoes. You can wear the wrong size — but not for long.

Mistake #2: Using the Wrong Tools (Or None at All)

Every watch modder has been guilty of this one. The screwdriver-as-spring-bar-tool moment. The kitchen knife moment. The “I’ll just be careful” moment.

And that’s usually followed by the “why is there a dent in my lug?” moment.

The Truth

Spring bars are deceptively strong. They’re designed to hold your entire watch in place under movement, sweat, and tension. So when you pry them out without proper leverage, they snap back — and your tool slips.

The damage is almost always the same:

- Micro-scratches around the lug holes.

- Bent spring bars.

- Loss of confidence.

The Right Way

Invest in a proper spring bar removal tool. Use tape around the lugs if you’re nervous. Push inward, not downward — your goal is to compress, not pry.

Inside Sugargoo’s watch repair tools section, you’ll find full kits designed for beginners and pros alike — precision tips, fine-tuned tension, and spare forks when you inevitably lose one under your desk.

Because the truth is simple: good tools don’t just prevent mistakes — they make you want to learn.

Mistake #3: Forcing the Spring Bar

This one’s painful — literally and emotionally. Every new modder, at some point, presses too hard.

The spring bar doesn’t fit, so you push. It slips, scratches the case, or worse — shoots across the room like a bullet.

You stare at your hand, your watch, and the floor, wondering where your confidence went.

The Real Problem

It’s not the bar’s fault. It’s angle and alignment. Most cases have micro-angled lug holes, meaning the bar needs to seat diagonally, not straight. If you force it flat, it jams against the wall of the hole.

How to Feel the Fit

When inserting a new strap:

- Place one end of the bar into its lug hole.

- Compress the other side gently with your tool.

- Wiggle slightly until you hear or feel the click.

If it doesn’t click, stop. Recheck the hole alignment or the strap’s end shape.

You can practice this on a spare case from Sugargoo’s custom watch part section — learning with less fear is the best way to build touch.

Pro Insight

Tension should never come from force — it should come from control. A true watchmaker doesn’t fight the spring bar; he persuades it.

Mistake #4: Ignoring Curvature and Fit

This one separates beginners from those who care about design.

Your watch isn’t just a face — it’s geometry. The case has curves. The strap should follow them. Yet most people buy straps based purely on color or price, ignoring curvature.

That’s why you sometimes see watches with gaps between the strap and the case — the so-called “floating lugs” look. It screams amateur modding.

The Aesthetic Fit

Rubber straps curve naturally for dive watches. Leather straps should hug dress cases softly. Steel bracelets need precise links to align with lug angles.

The Functional Fit

A misfit strap doesn’t just look wrong — it behaves wrong. It tugs outward under motion. Over time, that leads to:

- Stress on lugs.

- Uneven wear.

- Spring bar ejection during impact.

Think of it as biomechanics for watches. The strap is your wrist’s joint; if it’s misaligned, the whole body moves wrong.

Mistake #5: Forgetting Strap Care and Rotation

This one’s silent — it doesn’t hurt your watch today, but it will in six months.

Most modders are obsessed with swapping straps, not maintaining them. You take off a leather strap after summer heat, toss it in a drawer, and forget. By winter, it’s dry, stiff, maybe even cracking.

The Nature of Material

Leather, rubber, steel — all live differently:

| Material | Weakness | Care Tip |

|---|---|---|

| Leather | Sweat, moisture | Wipe daily, condition monthly |

| Rubber | UV exposure | Keep out of sunlight |

| Steel | Scratches, salt | Rinse after swimming, dry fully |

Every strap deserves a pause — a rotation. Owning multiple straps isn’t vanity; it’s preservation.

Keep them in watch boxes or storage cases. Clean gently with watch cleaning cloths after every wear. Your strap ages the way you treat it — and so does your craft.

What These Mistakes Really Teach You

Each of these mistakes — wrong width, bad tools, forcing bars, ignoring fit, neglecting care — looks small. But together, they reveal the deeper truth about modding: It’s not about precision; it’s about patience.

When you change a strap, you’re not just changing style — you’re learning balance. Balance between strength and gentleness. Between function and aesthetics. Between what you want, and what the watch is willing to give.

“Every watch teaches you how it wants to be held,” my mentor once said. “If you listen, you’ll stop scratching and start understanding.”

Where to Find Quality Parts & Tools

The watch modding world is full of shortcuts — cheap straps, knockoff tools, fake gaskets. But precision doesn’t tolerate fakes.

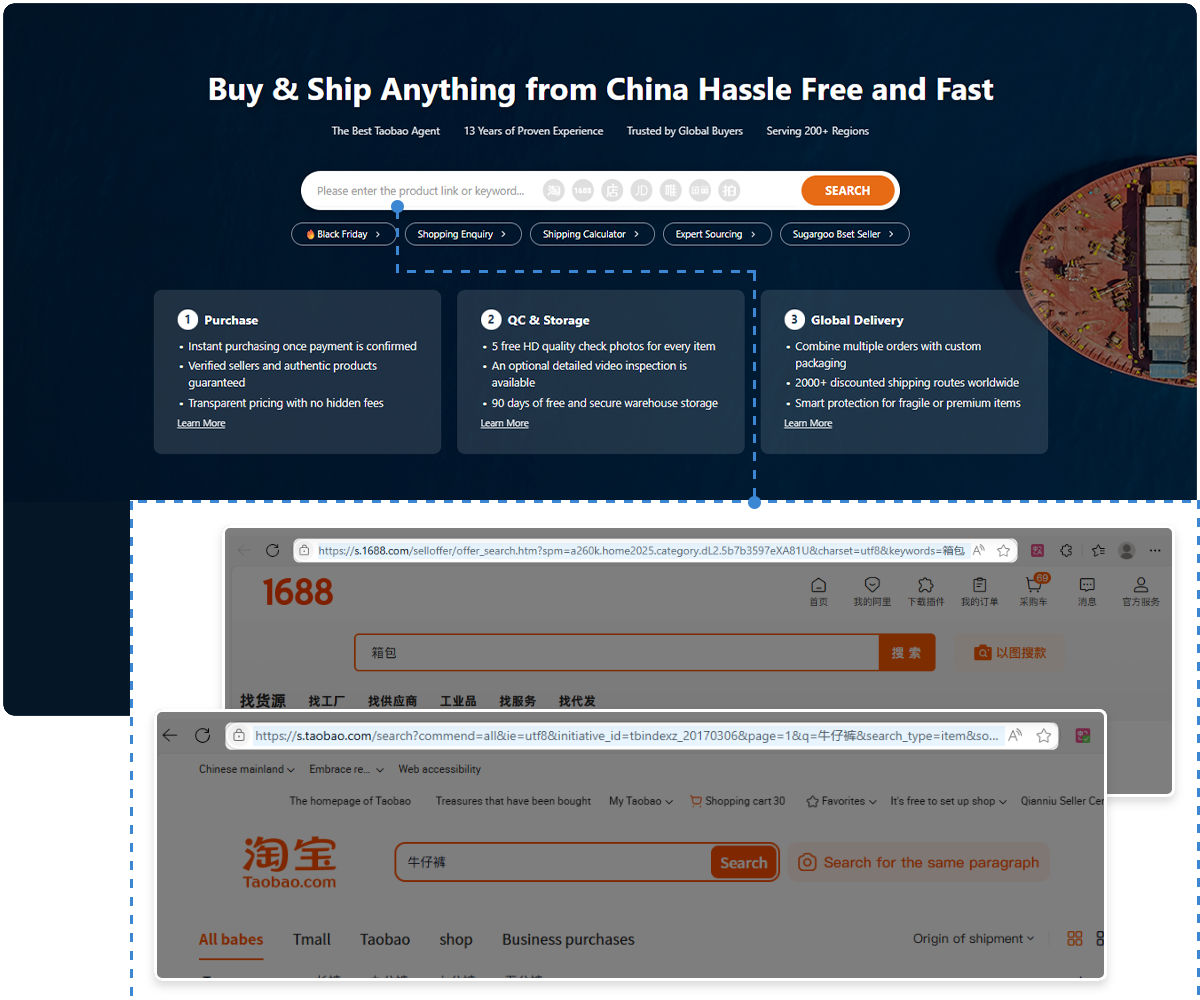

That’s why serious builders source through Sugargoo, the trusted Taobao agent for real modders.

You can:

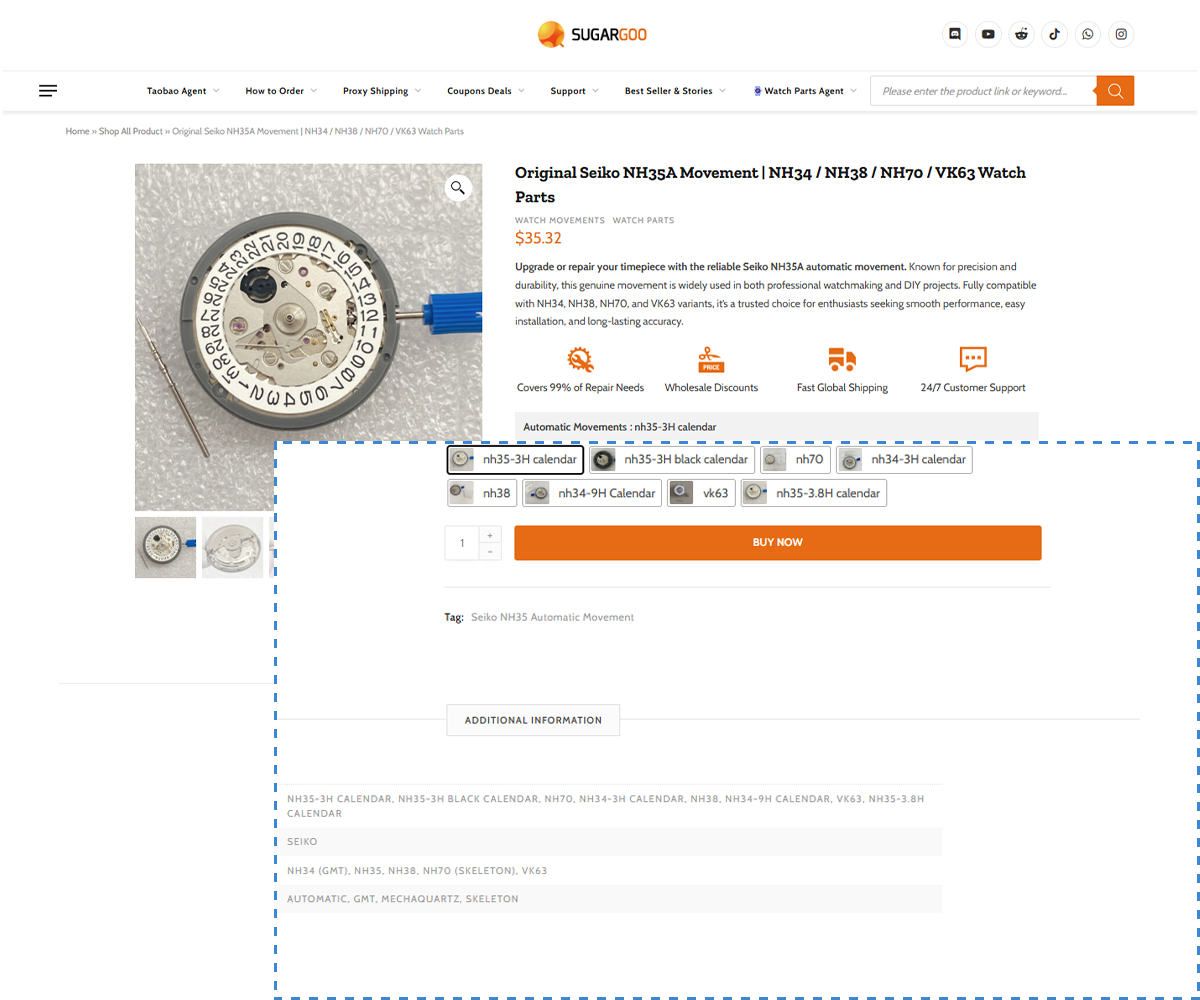

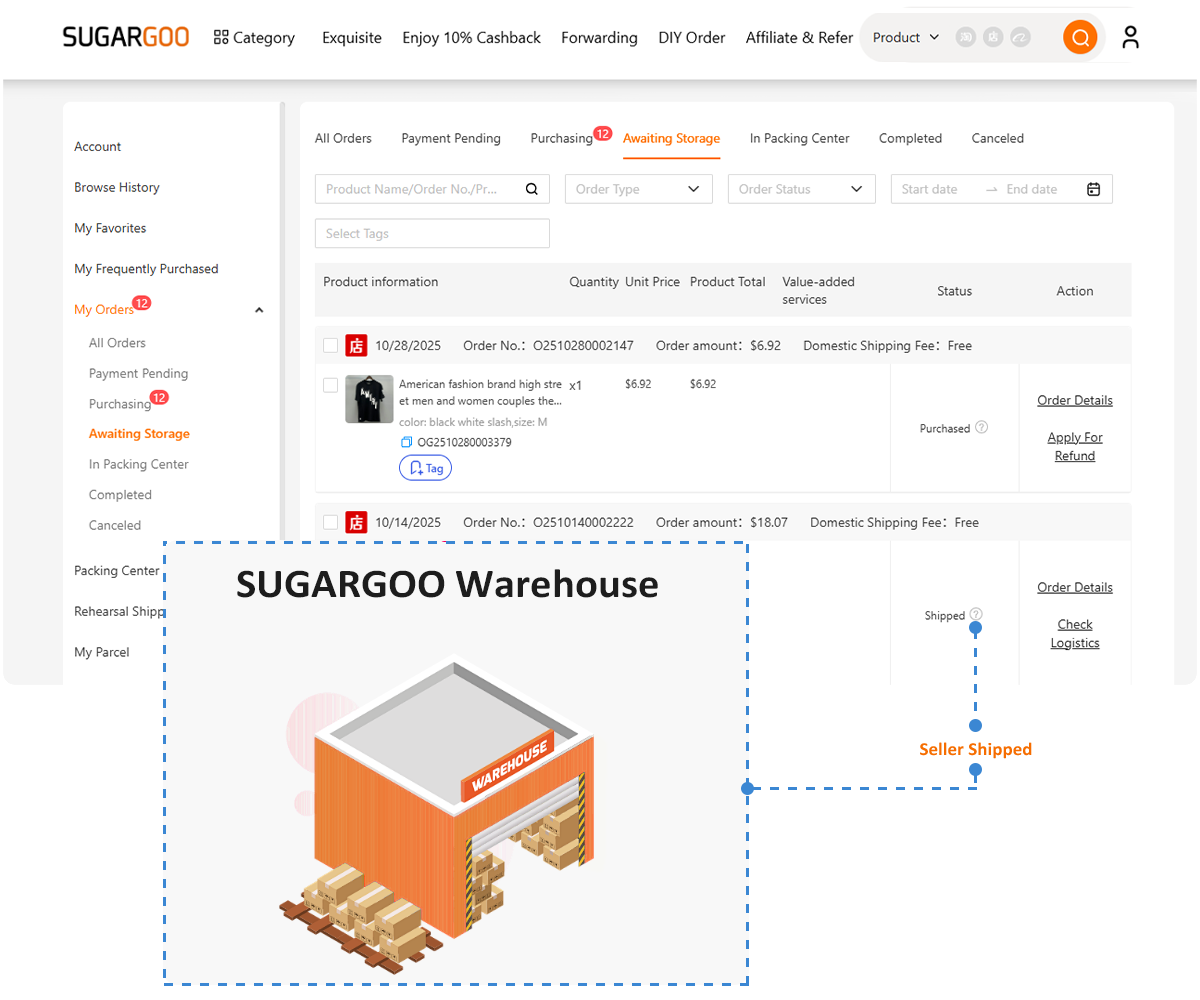

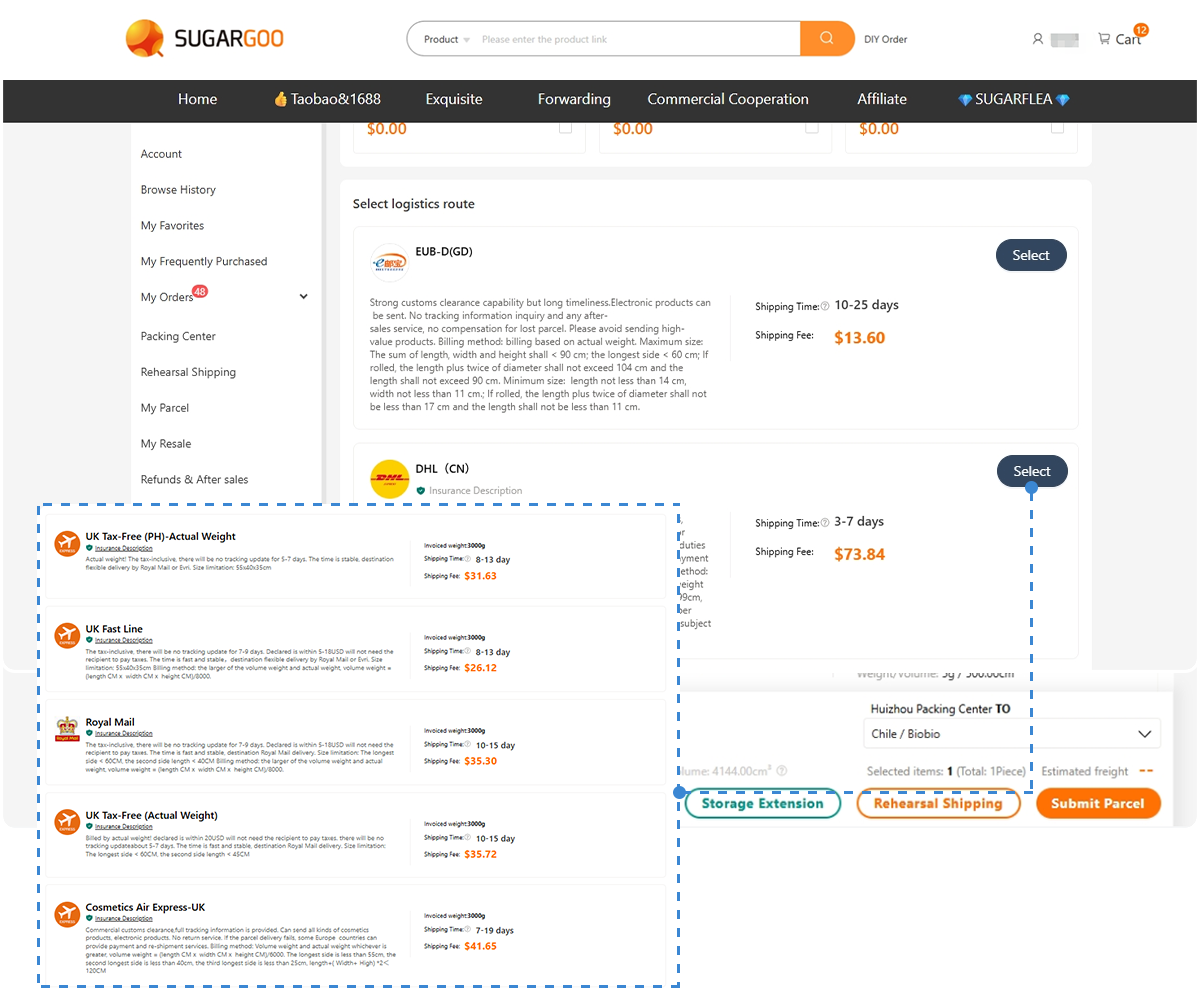

- Order Seiko NH35-compatible straps, spring bars, and tools directly from verified suppliers.

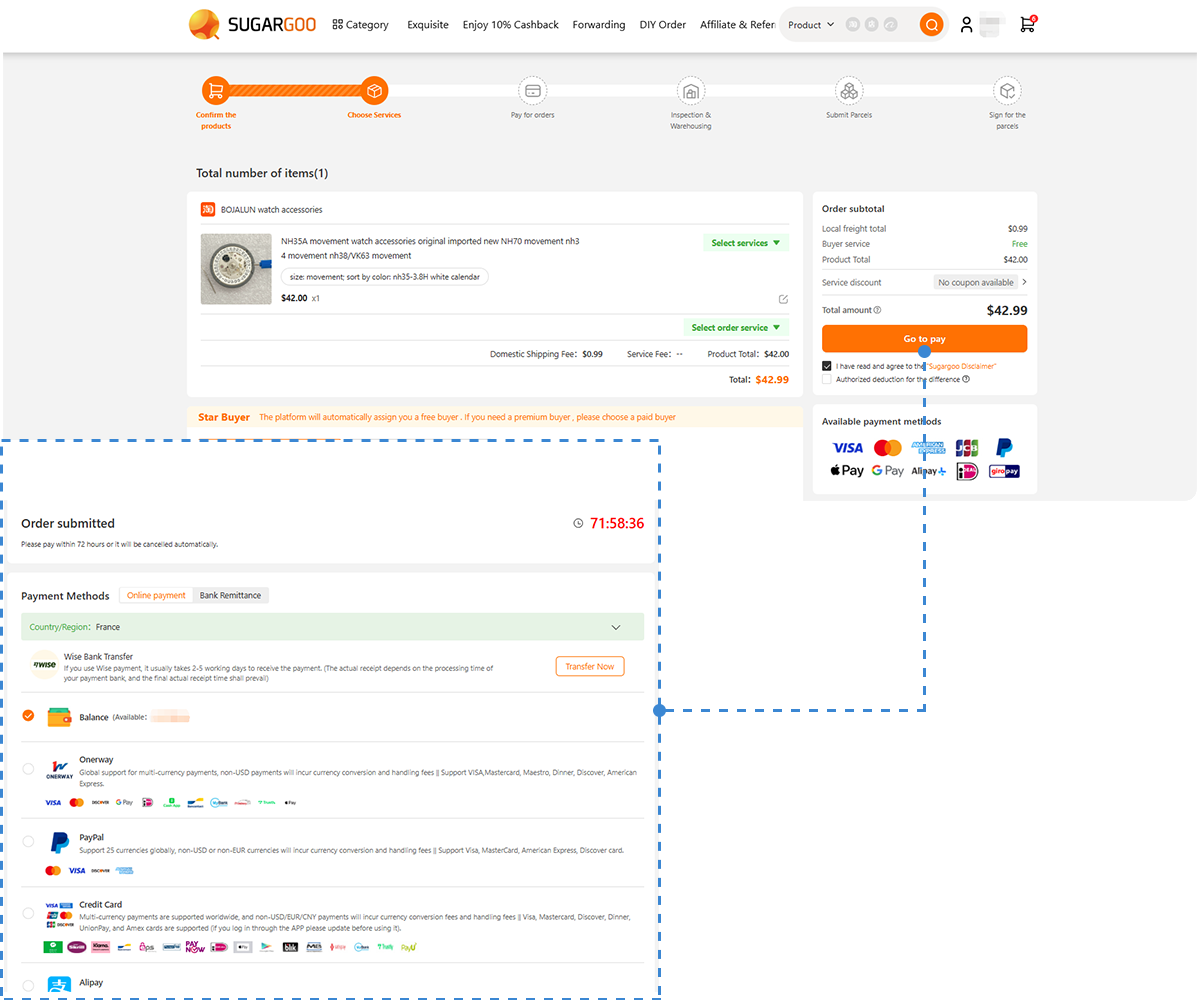

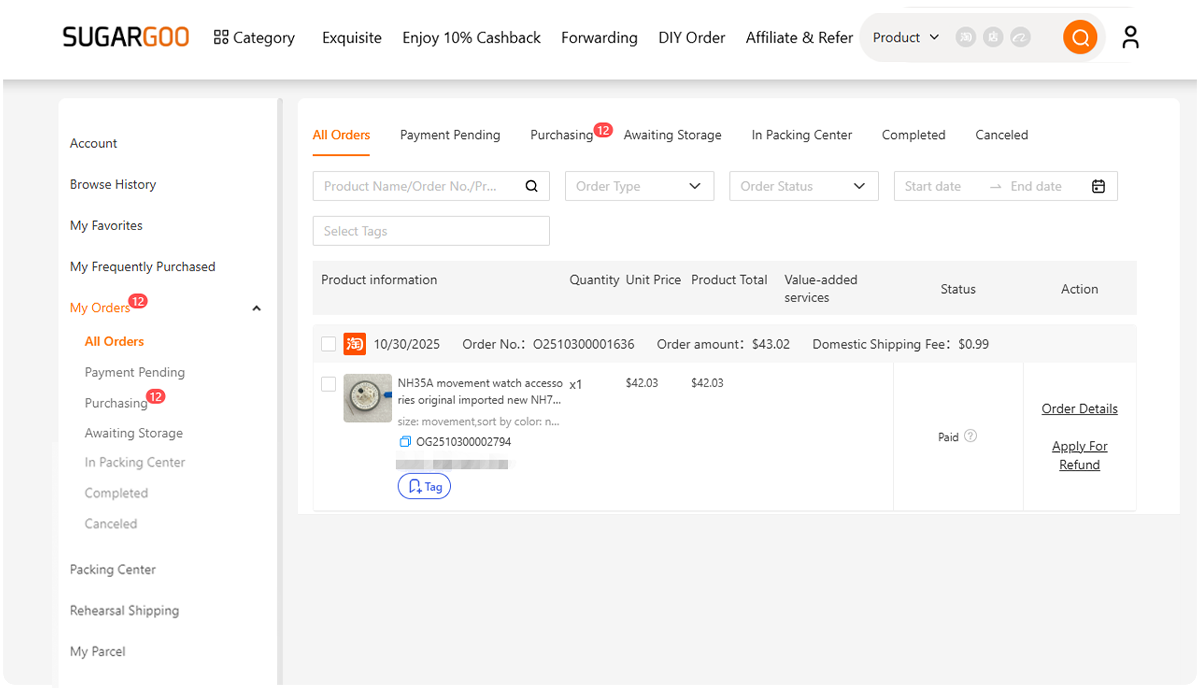

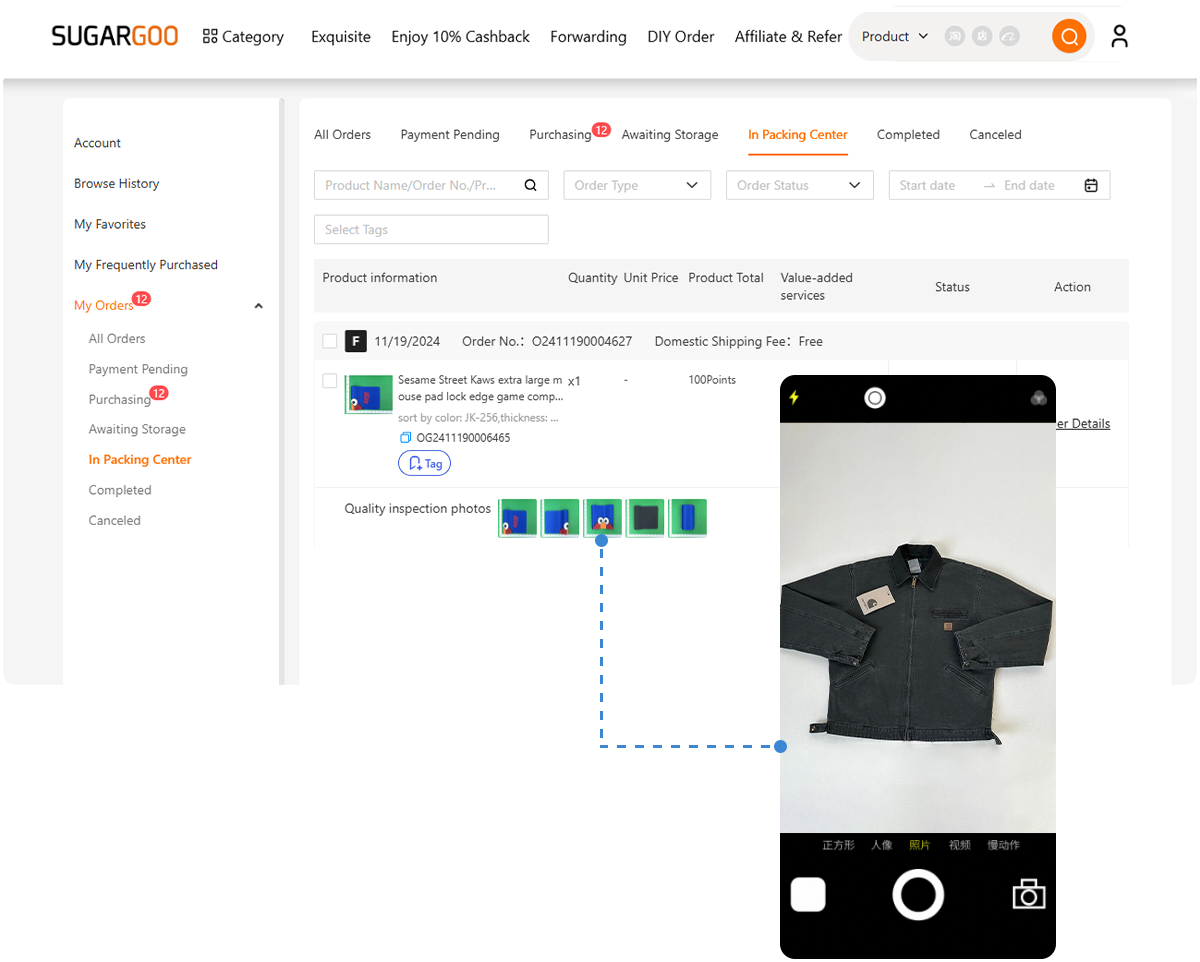

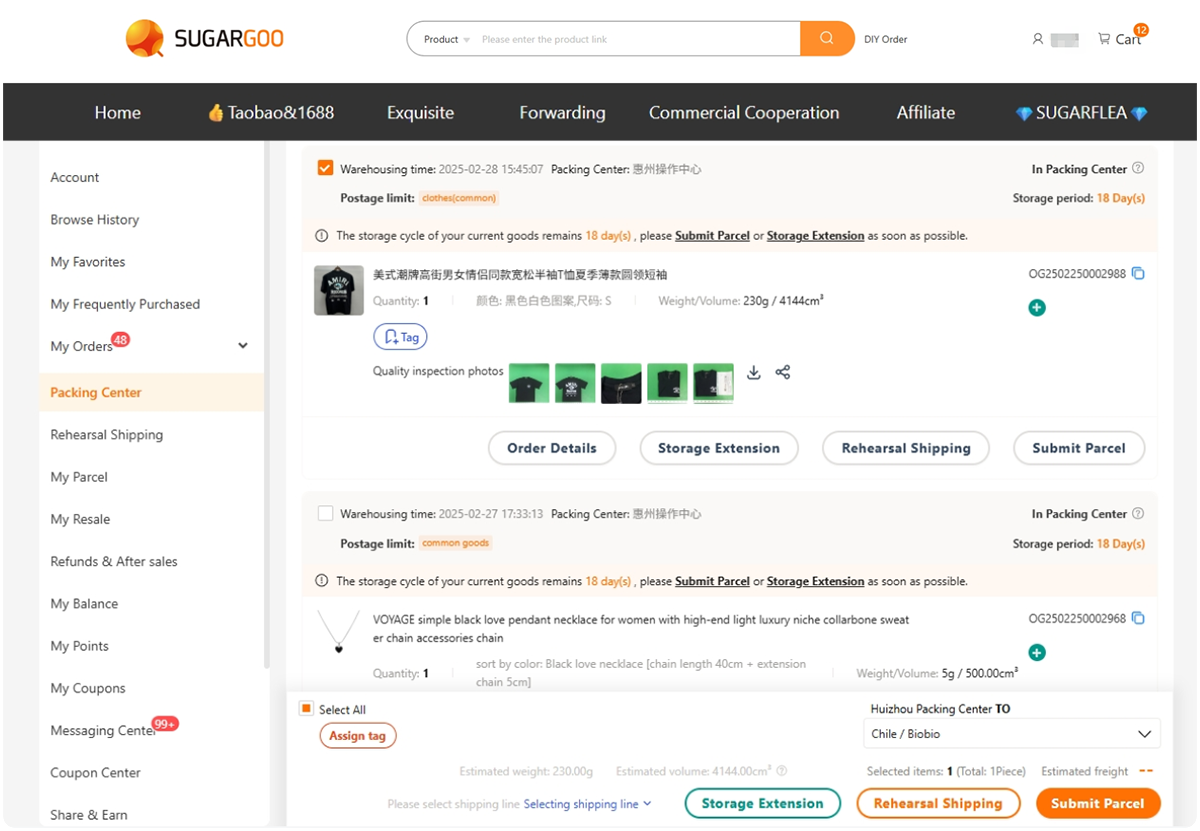

- Request quality control photos before shipping. (See our QC guide.)

- Combine multiple orders using Sugargoo’s order combine service.

- Access brands that rarely sell internationally.

Don’t guess what fits — source where modders do. Register here to explore thousands of authentic watch parts and start modding smarter.

The Philosophy Beneath the Straps

Every scratch, every mistake, every misplaced spring bar — it all adds up to something beautiful. It’s your apprenticeship under time itself.

Changing a strap may look simple, but it’s everything watchmaking stands for: precision, patience, and the courage to try again.

When you press that final bar in and feel it click, you’re not just connecting leather to steel — you’re connecting yourself to a tradition that’s hundreds of years old.

That’s why every time I swap straps, I still pause for a second before I push the bar. Because in that small moment, between risk and reward, you remember what craftsmanship really means: listening to the small things that most people ignore.