Look around the modern watch world, and you’ll notice something quietly revolutionary.

It’s no longer about which brand name sits on the dial — it’s about who built it.

A generation that once lined up for Rolex releases and Omega collabs is now spending their weekends assembling Seiko NH35 custom builds at home, discussing lug curvature and sapphire distortion in online groups.

The future of watches isn’t mass-produced. It’s personal, crafted, and driven by passion — one build at a time.

The End of “One-Size-Fits-All”

For decades, the luxury watch industry ran on exclusivity.

Limited editions, brand prestige, and waitlists defined value.

But modern collectors — especially the digital generation — see things differently.

They don’t want to own what everyone else has.

They want to wear something that represents them.

Even affordable microbrands now face this challenge: when every diver looks like an homage, and every pilot watch uses the same ETA 2824, identity blurs.

Custom builds solve that.

They make time personal again.

It’s the same cultural shift we’ve seen in sneakers, guitars, and even cars — from buying to building.

The Rise of the Builder Generation

Twenty years ago, customizing a mechanical watch required a workshop and decades of training.

Today, a few online tutorials, a toolkit, and an NH35 base movement are enough to start.

The democratization of watchmaking isn’t theoretical — it’s happening right now.

With open-source components, modding kits, and suppliers like Custom Watch Part, enthusiasts can build, swap, and experiment with design ideas once reserved for manufacturers.

This is craftsmanship without permission — and it’s changing how people relate to mechanical time.

They’re not customers anymore.

They’re creators.

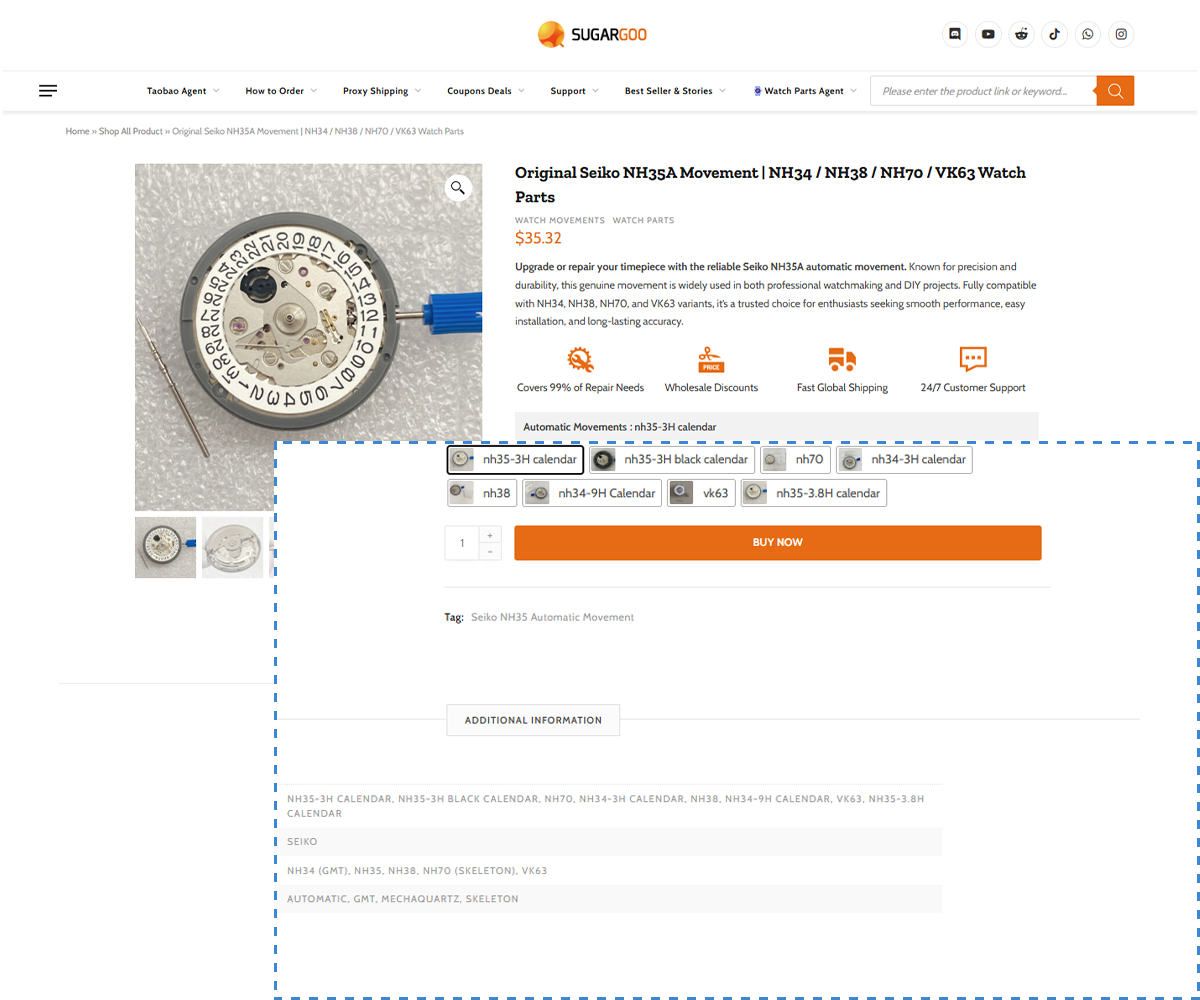

Seiko NH35: The Engine of the Movement

Every cultural movement needs a catalyst, and in custom watchmaking, that catalyst is the Seiko NH35.

Reliable, affordable, endlessly compatible — it’s the mechanical equivalent of the LEGO brick.

With countless cases, dials, and hands designed to fit it, modders can build everything from vintage divers to minimalist dress pieces.

A basic NH35 can become a work of art through creativity alone:

a matte black case, double-domed sapphire crystal, brushed steel bezel, and hand-lumed sandwich dial.

It’s the proof that craftsmanship and affordability can coexist.

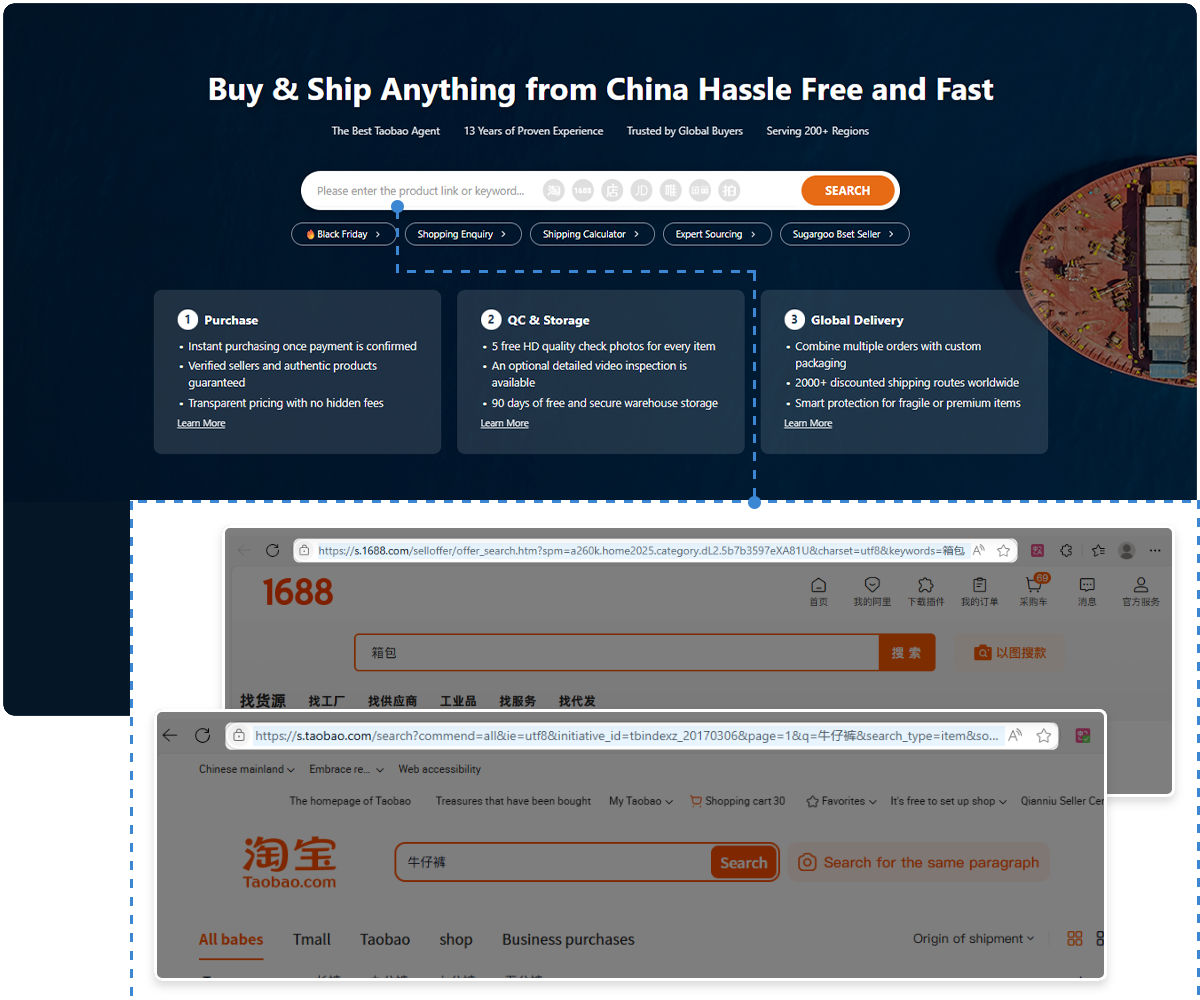

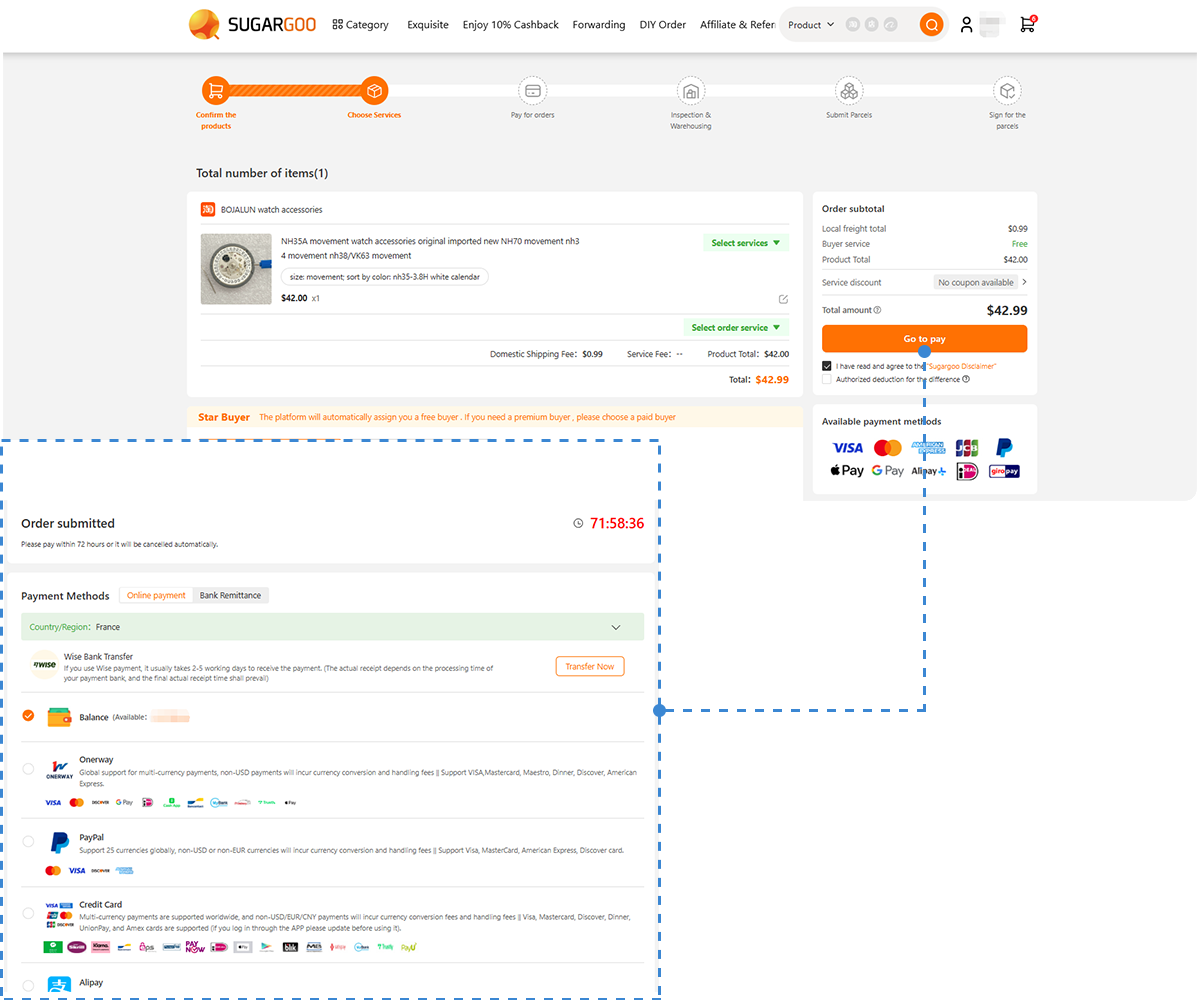

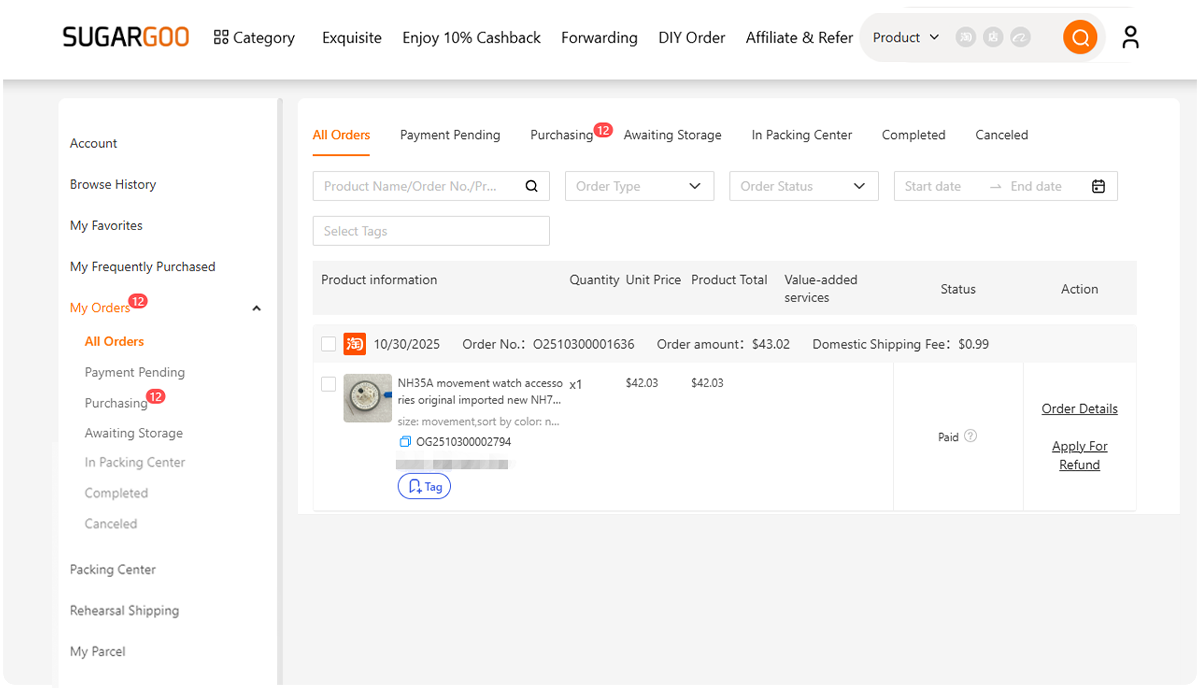

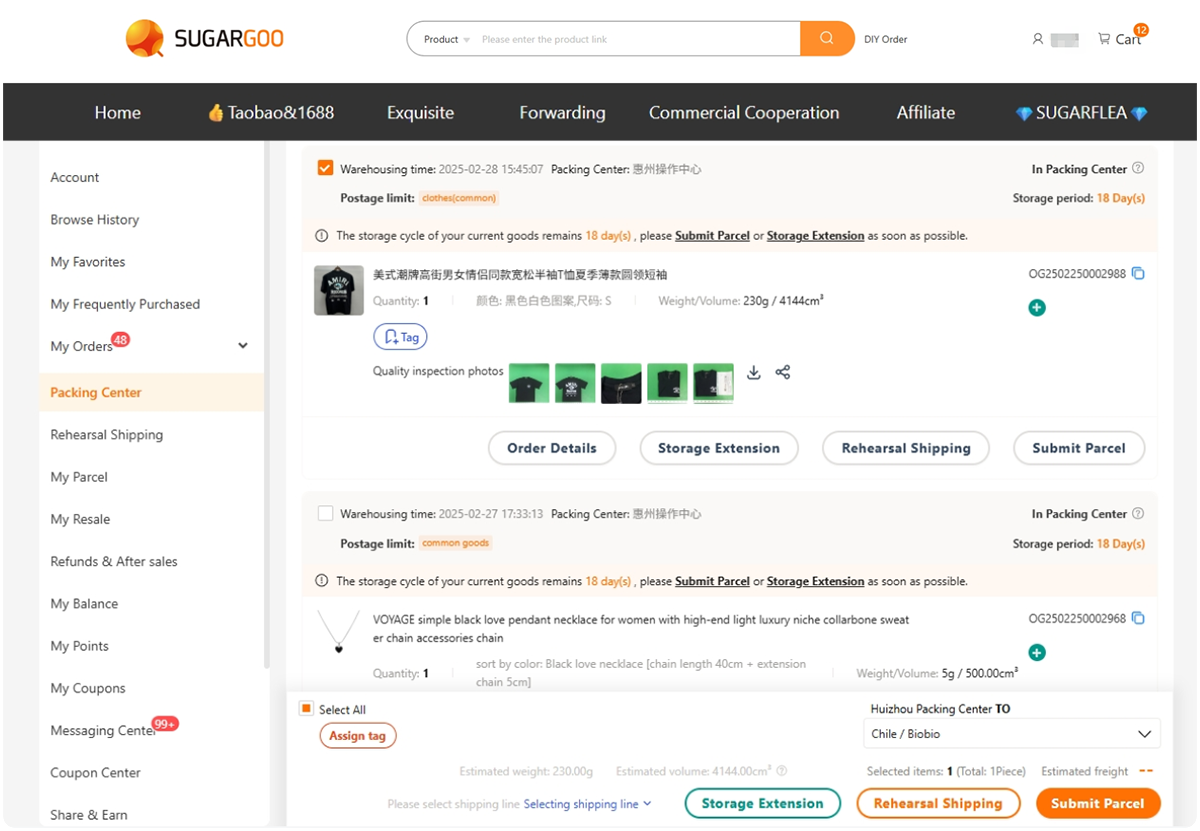

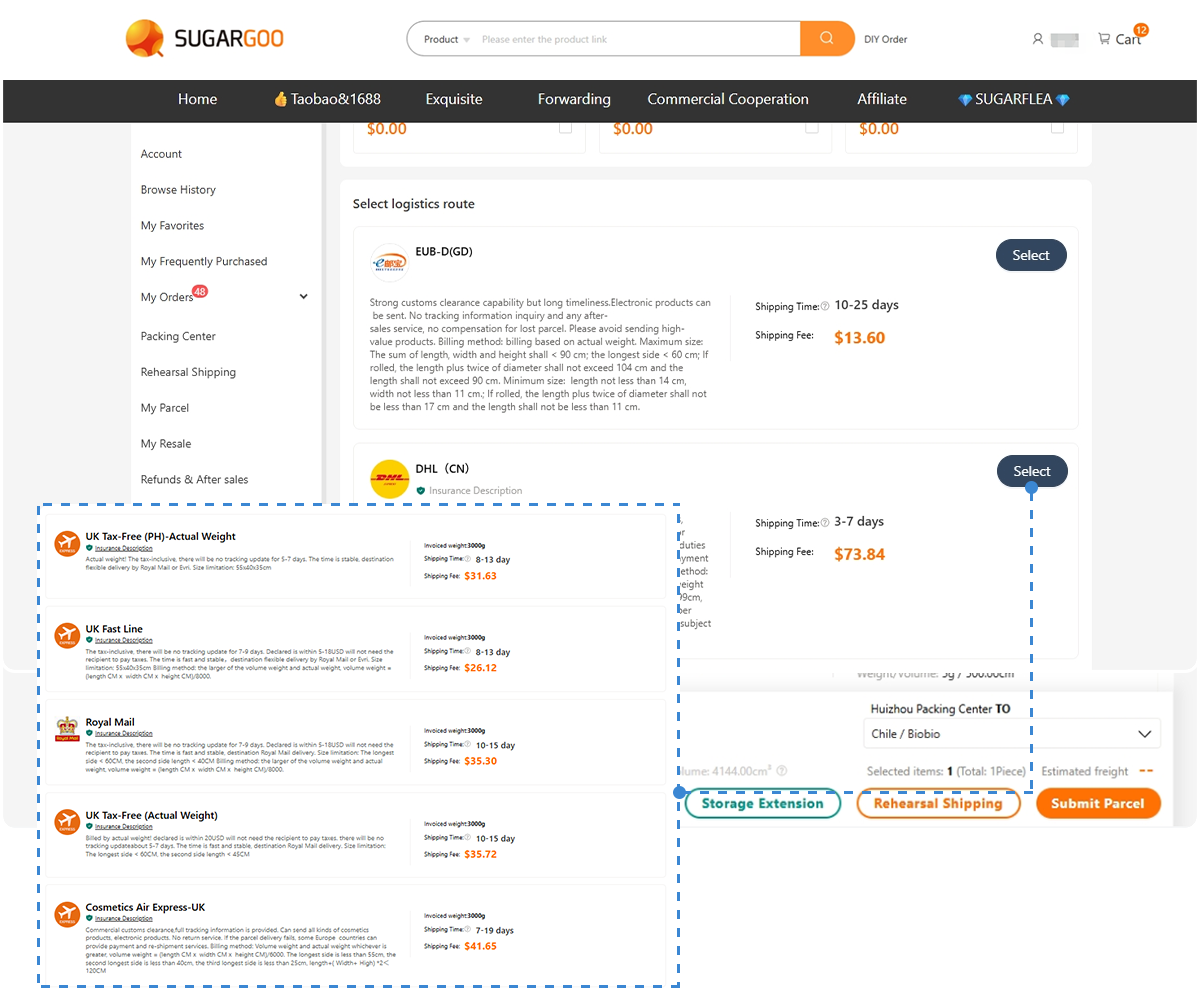

You can find compatible parts in Watch Movements and Watch Cases Replacement, or even commission rare variations through taobao agent custom watch suppliers that specialize in movement tuning and QC inspection.

The Return of Touch: Why Custom Builds Feel Different

In an era of screens and automation, assembling a watch by hand reconnects people with tangible creation.

When you press a crown into a stem or align watch hands just right, you’re not just “building” — you’re feeling time.

That tactile satisfaction — the soft click of a bezel, the perfect alignment of lume — has become therapeutic for many.

It’s a craft that rewards patience, precision, and respect for detail.

And unlike digital hobbies, every outcome is physical.

When you finish, you don’t have pixels — you have a machine that beats in your hand.

Aesthetics of Authenticity

There’s something deeper than aesthetics in a custom mechanical watch.

It’s authenticity.

Mass-produced watches chase perfection — symmetry, polish, flawless printing.

Custom builds celebrate character — the imperfect brushing, the subtle mismatch, the marks of creation.

Collectors are tired of factory gloss. They crave authorship.

That’s why photos of DIY Seiko mods often get more engagement than brand campaigns.

They tell a story of individuality.

They say, “This wasn’t designed in a boardroom. It was built at a desk at 2 a.m.”

It’s an authenticity the luxury industry can’t replicate.

Craft Meets Community

Custom watch building isn’t a lonely pursuit — it’s a social movement.

Communities on Reddit, Discord, and Facebook have become classrooms, studios, and galleries.

Builders share failures as openly as triumphs: scratched crystals, misaligned bezels, broken stems.

And in that transparency, skill grows.

When someone in Germany helps someone in the Philippines fix an NH36 crown height, you realize this isn’t just a hobby — it’s a global craft.

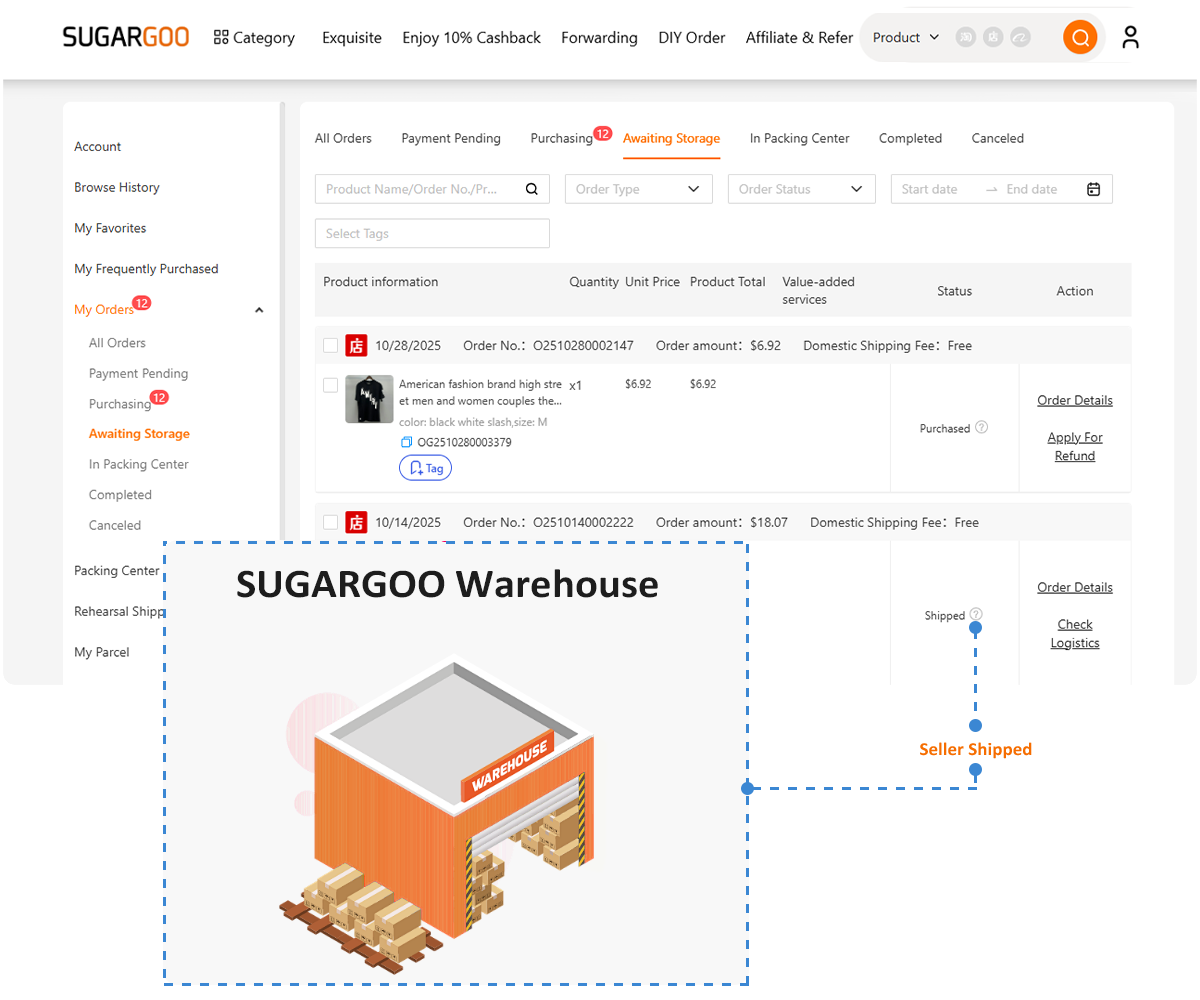

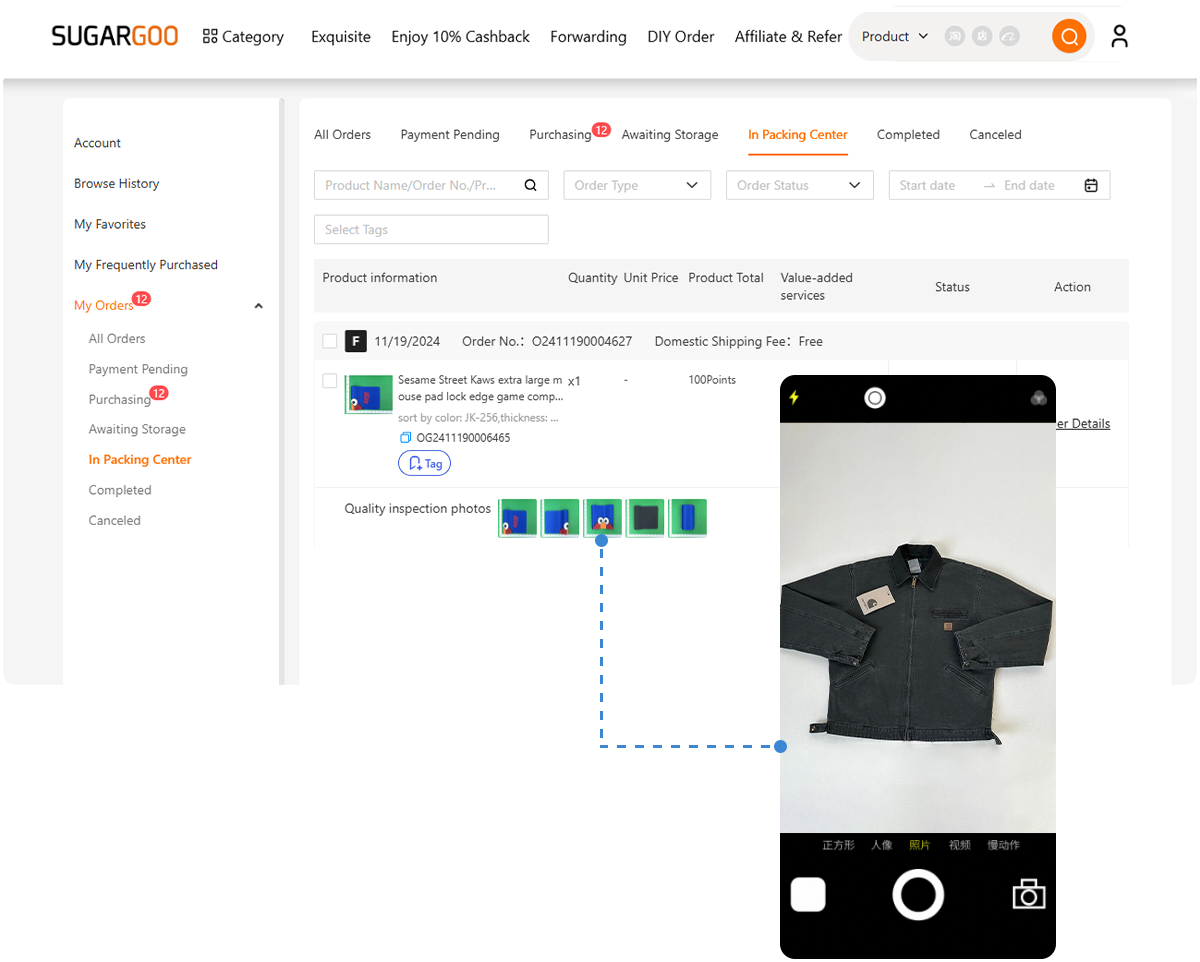

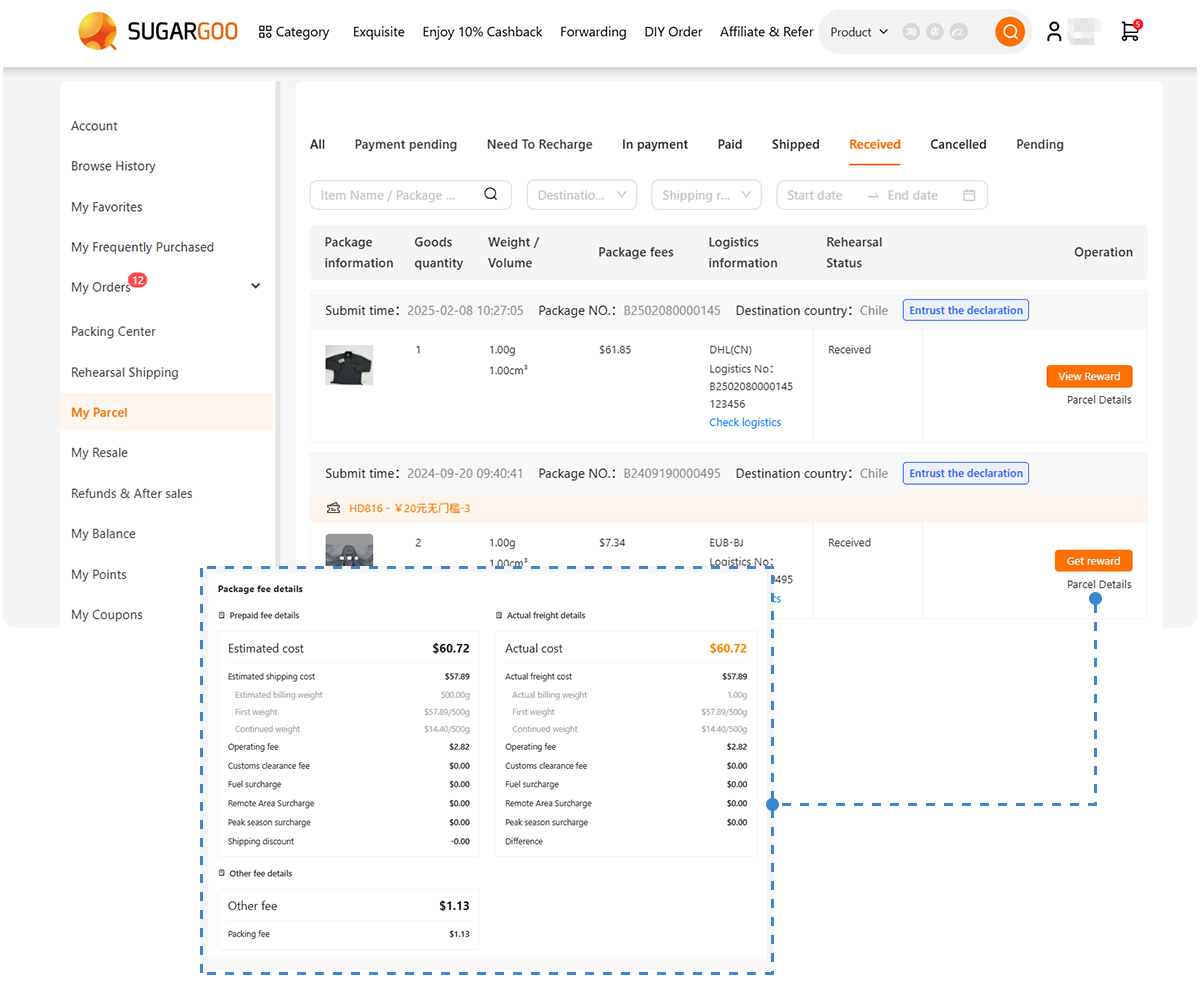

Platforms like Sugargoo and taobao agent watch part marketplaces have accelerated this network by making sourcing easier.

You no longer need manufacturer connections — just curiosity and willingness to learn.

Technology: The Hidden Partner in Customization

3D printing, CNC machining, and AI-assisted design have quietly entered the scene.

Today, enthusiasts are printing prototype dials, engraving custom casebacks, and designing bezel inserts with online CAD tools.

Tomorrow, they’ll use AI to generate new lug shapes, pattern ideas, and lume textures.

Small workshops that once made OEM cases now cater to custom orders — often collaborating with microbrand founders and hobbyists alike.

The future isn’t just modding existing watches — it’s inventing entirely new ones.

Imagine:

AI-generated dial textures

3D-printed movement holders

Custom-fitted bezels machined from titanium

Personalized packaging designed for each build

That’s not the future — it’s already happening.

The Sustainability Factor

Custom builds also align with a growing sustainability mindset.

Instead of constantly buying new, modders reuse, upgrade, and reimagine existing watches.

An old Seiko diver becomes a new skeletonized masterpiece.

A scratched sapphire crystal gets replaced instead of discarded.

Repair becomes creation.

Sustainability becomes style.

This “slow watchmaking” culture challenges disposable consumption — proving that mechanical art can be ethical and enduring.

Beyond Modding: Toward Independent Watchmaking

What starts as a hobby often evolves into microbrand entrepreneurship.

Many of today’s small-batch watch brands began as modders — people who wanted to share their personal aesthetic with the world.

The line between builder and watchmaker is blurring fast.

And that’s healthy for the industry.

It decentralizes creativity, pushing innovation from the bottom up instead of top down.

As long as there’s a movement that can be customized — NH35, ETA, Miyota, or ST36 — independent creators will keep reimagining what a watch can be.

The Future: Personalization as Luxury

Luxury used to mean scarcity.

Now, it means personal connection.

A $400 custom-built diver can mean more to its owner than a $4,000 mass-produced Swiss piece — because it carries a story.

Tomorrow’s collector won’t ask “What brand is that?”

They’ll ask “What’s your build?”

And the answer — the mix of parts, inspiration, and hours spent — will matter more than any logo.

That’s where the value shifts.

Brands will start offering modular platforms.

Communities will trade parts as easily as NFTs.

Creators will sell limited custom dials or hands.

AI will design personal builds that exist nowhere else.

The age of ownership is ending.

The age of authorship has begun.

A Note to the Next Builder

If you’ve ever hesitated — wondering if you’re “qualified” to mod a watch — stop.

Every expert started with one shaky hand and a cheap toolkit.

What matters isn’t perfection.

It’s curiosity.

Start with a movement from Watch Movements, a case that excites you, and a vision of what your ideal watch feels like.

Then make it real.

Because the moment you build your first watch, you stop being a consumer.

You become a maker of time itself.

Final Thoughts: The Craft That Belongs to Everyone

In the past, time was something we wore.

Now, it’s something we create.

The future of watchmaking won’t be ruled by marketing campaigns or celebrity ambassadors.

It’ll be shaped by thousands of individuals, quietly modding, building, and crafting at home — each telling their version of what time means.

And maybe that’s what makes it so beautiful:

a movement powered not just by gears and springs, but by imagination.

Because in the end, the future of watches isn’t mass-produced.

It’s handmade — one heartbeat at a time.

Ready to start your journey? Check out our guide to start watch modding and join the movement!